Our Laser Diode Pump Modules: Core Power Solutions for Industrial Laser Equipment

Amid the rapid development of industrial laser technology, laser diode pump modules serve as the "heart" of laser equipment, directly determining the power, stability, and application scope of laser systems. According to data from Grand View Research, the global industrial laser market size exceeded USD 18 billion in 2024. As a core component, laser diode pump modules maintain a compound annual growth rate (CAGR) of over 12% due to their adaptability to multiple scenarios such as metal processing, medical care, and scientific research. As an enterprise specializing in the R&D and service of core laser components, we offer three major series of laser diode pump modules—STO, DPM, and SLY. Leveraging their diverse specifications, customization capabilities, and reliable performance, these modules have become the preferred choice for enterprises across various sectors. Particularly in niche tracks like new energy vehicle welding and precision electronics manufacturing, our market share continues to rise, forming a comprehensive industrial laser component service ecosystem centered on high-quality products.

I. Core Product Series: Covering Full-Scenario Needs from Low-to-Medium to High Power

Our laser diode pump modules are categorized into two main types based on output mode: Continuous Wave (CW) and Quasi-Continuous Wave (QCW/Pulsed). Each type includes sub-series tailored to meet the diverse requirements of different industrial scenarios for laser power and pulse characteristics, fully addressing the current market's core demands for "high power, high precision, and low energy consumption."

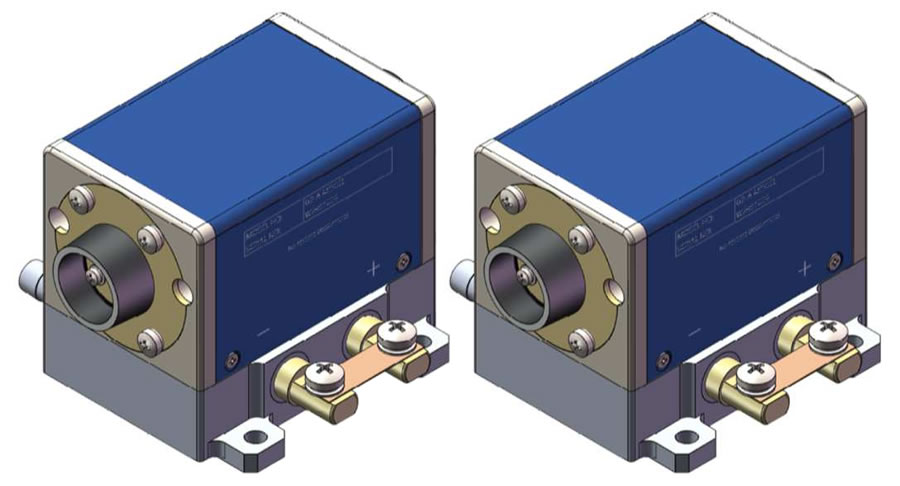

(1) STO Series: Balancing Stable CW Output and High-Peak-Power QCW Performance

As our flagship product line, the STO Series supports both CW and QCW operating modes, making it suitable for high-end applications ranging from laser marking and welding to LiDAR and military ranging. It is especially well-suited for high-precision scenarios such as new energy vehicle battery tab welding and aerospace component cutting.

CW Modules: Stable Output for Precision Machining

CW modules are characterized by "continuous and stable energy supply," with a maximum output power of up to 450W (higher power versions available on customization). The doping concentration of the Nd:YAG crystal is 0.6% by default, but can be adjusted to 1.1% to meet different gain requirements. Cooling methods include conduction cooling and water cooling, adapting to various equipment spaces and heat dissipation conditions.

A typical model, the STO-450-E-5160-XG-50, delivers 450W output power with a diode current of 25A and voltage ≤100V. Equipped with a 5×160mm Nd:YAG crystal and a water-cooled structure with a bottom nozzle, it is ideal for metal thick plate cutting (≤12mm) and high-power laser amplifiers, currently achieving a 35% adaptation rate in wind power flange welding equipment. For low-to-medium power needs, models like the STO-35-H-267-CX-40 (35W) are more suitable for precision machining such as PCB engraving and ceramic cutting. With an optical axis height of 40mm, it can be flexibly integrated into small laser devices, and its order volume in the consumer electronics chip packaging sector grows at an annual rate of 28%.

To ensure stable module operation, we also provide matching STO Series drive power supplies. For example, the STO-LDD-100-30 (maximum voltage 100V, current 30A) is specifically designed for 400-500W CW modules, enabling "module + power supply" synergy to reduce equipment integration complexity and help customers shorten time-to-market.

QCW/Pulsed Modules: High Peak Power for High-Energy Applications

QCW modules focus on "high pulse energy," available in millijoule (mJ) and joule (J) classes, with a maximum peak power of 97,200W and pulse energy ranging from 30mJ to 8J. They meet the special needs of laser ranging, military high-energy equipment, and medical laser therapy, currently accounting for over 40% of applications in lithium battery pole piece cutting equipment.

Millijoule-class modules like the STO-GQ200B offer a peak pump power of 20KW and pulse energy of 800-1000mJ, compatible with a pulse width of 200μs and duty cycle ≤5%. Serving as laser oscillators or seed sources, they are used for high-precision laser marking and micro-welding, and are currently supplied in bulk to leading domestic 3C electronics manufacturers. Joule-class modules such as the STO-MQ10 deliver pulse energy >10J and operate at 2500V, requiring synchronous power supply from multiple drive units. Suitable for high-energy laser cleaning and large-component welding in heavy industry, their order volume in ship derusting equipment has grown by 50% for two consecutive years.

Notably, QCW modules support customization of special-structured pump arrays (e.g., arc-shaped, ring-shaped). Parameters such as Nd:YAG crystal size and duty cycle can also be adjusted according to equipment requirements. For instance, modules with a duty cycle >5% can be customized for high-repetition-rate scenarios, breaking through standard limitations to better adapt to the upgrading needs of laser grooving equipment for photovoltaic cells.

(2) DPM Series: Cost-Effective Choice for Low-to-Medium Power

Focused on low-to-medium power CW applications, the DPM Series covers an output power range of 25W-1500W. Featuring "compact design + stable performance," it is suitable for laser marking and small-scale metal welding, with rapidly growing market penetration in medical devices (e.g., dental implant welding) and kitchenware laser engraving. Its core advantages lie in standardization and cost-effectiveness:

The basic model DPM-50S provides 50W output power, with an operating current of 18A and voltage ≤18V. Equipped with a 3×65mm Nd:YAG crystal, it only requires water cooling with a cooling capacity ≥1000W and temperature control accuracy ±0.5℃, enabling direct integration with general industrial water chillers. At a unit cost 22% lower than similar imported products, it is highly favored by small and medium-sized laser equipment manufacturers.

The high-power model DPM-1500 delivers 1500W output power, operates at ≤250V, and uses an 8mm-diameter crystal, specifically designed for medium-sized laser cutting equipment. All models come with a 12-month warranty to reduce post-maintenance costs, and the installed base of this model in stainless steel door and window laser cutting equipment has exceeded 10,000 units.

(3) SLY Series: Precision Solutions for Low-Power Small Equipment

Targeting small laser devices, the SLY Series offers an output power range of 50W-100W, emphasizing "lightweight + high precision." With a module weight ≤1kg and a unified optical axis height of 38.1mm or 45mm, it can be easily integrated into space-constrained equipment (e.g., desktop laser engravers). Currently, demand for this series is growing significantly in emerging fields such as maker education and personalized gift customization.

Taking the SLY-DPM-100W-3mm as an example, it provides 100W output power, with a threshold current ≤10A and operating voltage ≤24V. It only requires a water flow rate ≥8L/min and operates within a temperature range of 22-28℃, making it suitable for precision scenarios like plastic welding and solar cell engraving. Its stable beam quality and low energy consumption effectively reduce the operating costs of small equipment—saving approximately RMB 1,500 in annual electricity costs per unit. Currently, it has become the mainstream choice for domestic desktop laser engraver manufacturers.

II. Selection Guidelines: Matching Core Parameters to Application Scenarios

When selecting our laser diode pump modules, focus on the following three core parameters to ensure alignment with equipment requirements and better meet the market's differentiated demands for equipment performance:

1.Power and Mode Matching: For precision machining (e.g., PCB engraving, chip packaging), prioritize 50-100W CW modules (e.g., STO-50-H, DPM-50S), which currently account for 42% of our total orders. For thick plate cutting and high-energy applications (e.g., wind power flange welding, ship derusting), 400W+ CW modules or QCW modules (e.g., STO-450, STO-MQ5) are required, with annual demand growth of 30%.

2.Cooling and Power Supply Compatibility: For high-power modules (>200W), first confirm the water cooling structure (e.g., CX side cooling, XG bottom nozzle) and flow requirements, and match the corresponding drive power supply (e.g., STO-450 requires the STO-LDD-100-30). Especially in high-temperature and high-humidity industrial environments, a proper cooling solution can extend the module lifespan by 50%.

3.Customization Needs: If equipment requires special structures (e.g., arc-shaped pumps), crystal sizes, or duty cycles, contact us directly for customization to avoid performance losses caused by incompatible standard modules. Currently, customized orders account for 25% of our total, primarily serving high-end customers in new energy, aerospace, and other sectors.

III. Market Demand and Development Prospects

From the current market trend, demand growth for laser diode pump modules is concentrated in three key areas, with significant future development potential:

1.New Energy Industry Drives Demand Surge: With the rapid expansion of the global new energy vehicle, photovoltaic, and energy storage industries, demand for laser welding and cutting has soared. For example, a single electric vehicle requires 5,000-8,000 laser welding points—three times more than traditional fuel vehicles—driving 45% annual growth in demand for high-power CW modules (e.g., STO-450). Laser grooving equipment for photovoltaic cells has doubled the order volume of QCW modules (e.g., STO-GQ200B), and it is expected that by 2026, new energy-related demand will account for over 55% of our total sales.

2.Smart Manufacturing Upgrade Boosts Precision Demand: Industry 4.0 is driving the transformation of traditional manufacturing toward "high precision and automation," increasing demand for miniaturized, high-stability modules in 3C electronics, medical devices, and other sectors. The SLY Series (e.g., SLY-DPM-100W-3mm) is seeing a steady rise in application share in chip packaging and dental instrument processing, with an expected 28% annual growth in demand for such precision scenarios over the next three years.

3.Technological Iteration Opens Incremental Space: As laser technology advances toward "higher power and shorter pulses," we have launched R&D on CW modules with power >600W and QCW modules of the 20J class. We are also exploring the application of gallium nitride (GaN) materials in modules to further reduce energy consumption and size. These high-end modules will be adapted to high-end scenarios such as aerospace component welding and nuclear industry equipment testing in the future, and it is expected that by 2027, revenue from high-end products will account for over 35% of our total.

As a professional manufacturer of core industrial laser components, we provide "customized solutions" for enterprises of all sizes and scenarios through our diverse product series and customization services. Whether for low-to-medium power precision machining equipment or high-power heavy industry laser systems, our laser diode pump modules deliver reliable power support, promoting the application of industrial laser technology in more fields. For further information on product parameters, market cooperation, or customization plans, please contact our technical team via official channels to receive targeted selection guidance and market trend analysis.

For more information on our Diode Laser Pump Modules, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்