Our laser cleaning machine is a new generation product that is used for the purpose of material surface cleaning applications. It can be easily set up, operated and automated to remove surface dirt layers, which can be rust, grease, paint, primer, etc.

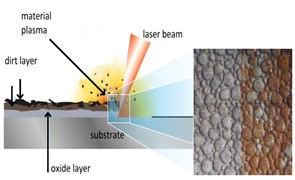

Principle:

Use of a high-power-density laser beam. When the laser beam contacts a surface, light/heat is absorbed by the surface.

Upon hitting the ablation threshold, molecular bonds in the surface are broken and ejected from the substrate ("vaporized")

The dirt layer usually has a lower ablation threshold than the substrate material. As such, it will vaporize earlier, with little damage caused to the substrate layer.

Advantages:

Non-contact cleaning, little damage to the base substrate layer.

Precise cleaning: Able to clean specific areas using pre-defined beam parameters.

Selective cleaning: Able to remove different dirt layers individually based on the ablation threshold.

High cleaning efficiency.

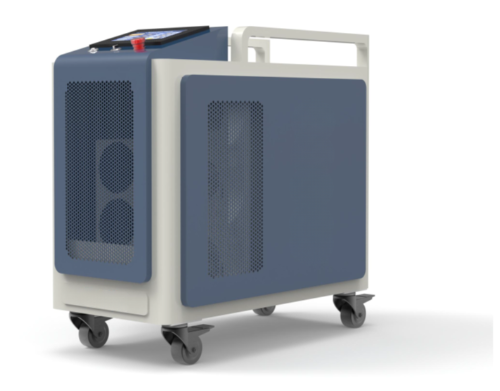

Stable and compact design, with minimal maintenance efforts.

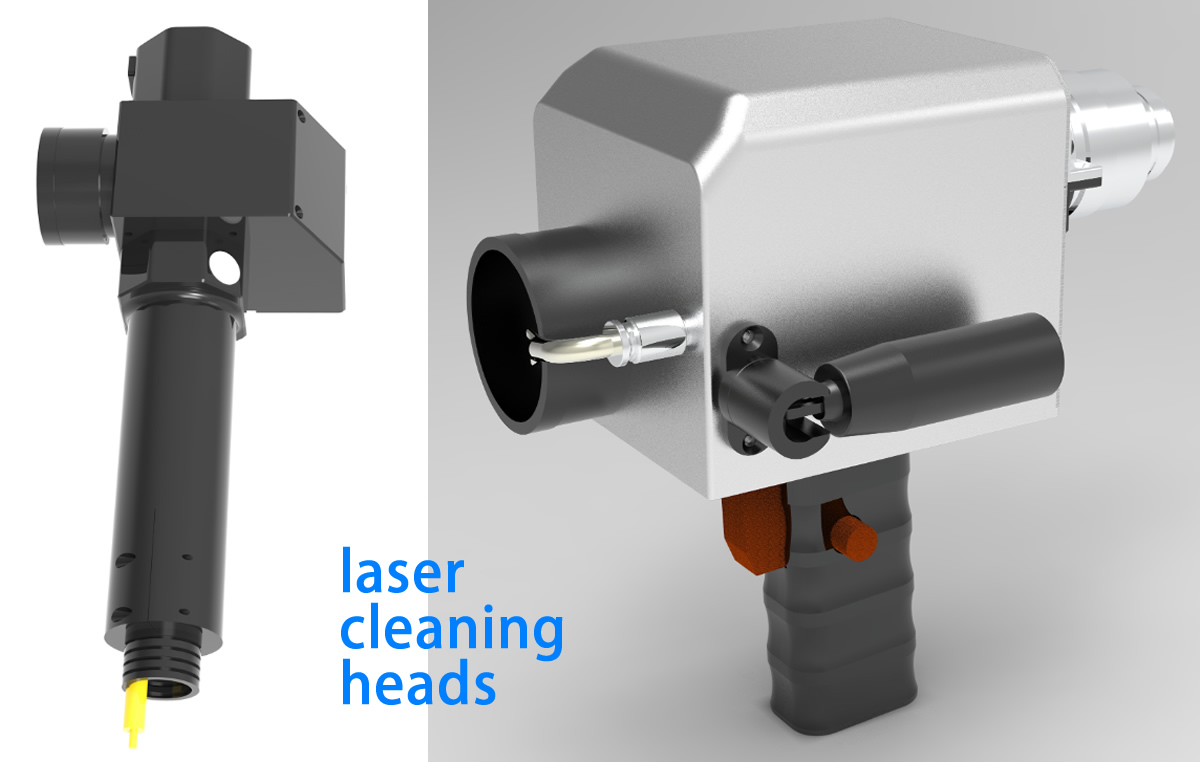

Easy to operate by operator or integrated with a robotic arm for automated cleaning.

No need to use chemicals, dry ice or other cleaning mediums. Few consumables, safe and environmentally friendly.

Sample Applications:

Our laser cleaning machines are mainly used for cleaning various metal surfaces with localized rust, paint, coatings, oil stains, oxide films, and other pollutants. It can also be used for cleaning surfaces of non-metallic substrates such as ceramics, glass and composite materials. Typical applications include cleaning natural oxide film on aluminium alloy before welding, cleaning black and gray oxide on battery trays after welding, cleaning welds on train bogies before non-destructive testing, cleaning automotive sheet metal parts before refurbishment, and cleaning steel components such as small holes and grooves that cannot be reached by wire brushes.

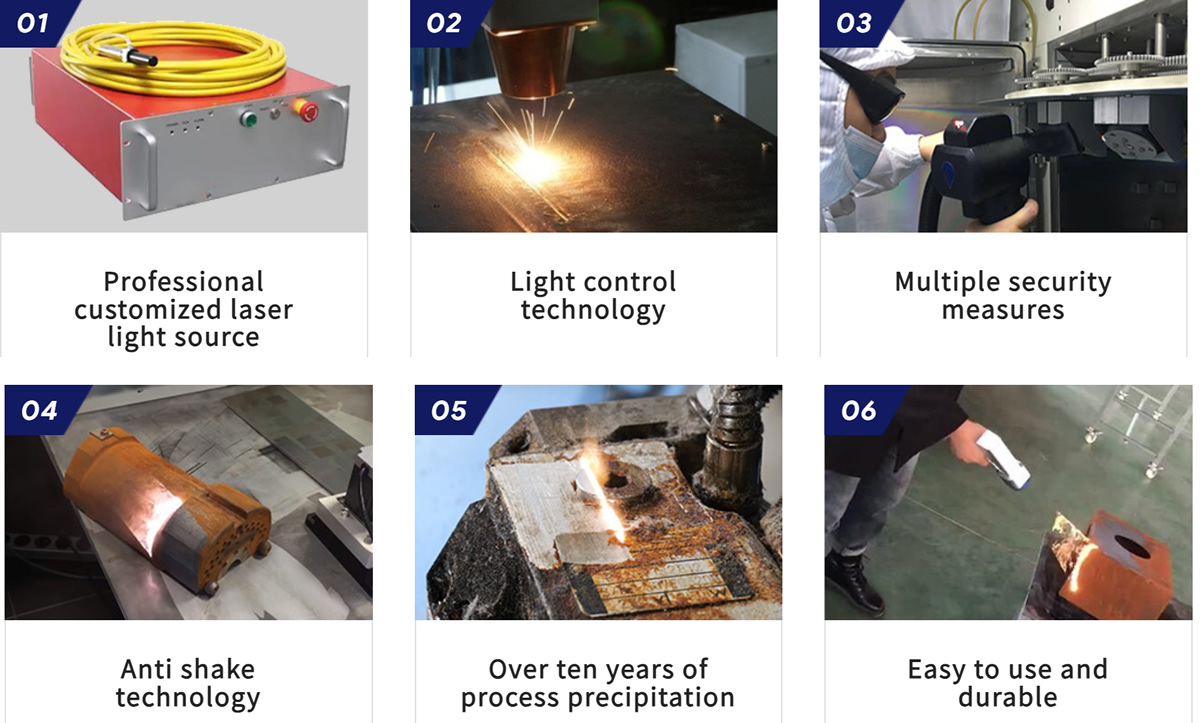

Product Advantages:

Product Specifications:

| Part number | CL-P-100W | CL-P-200W/300W | CL-P-500W/1500W |

| Laser power | 100W | 200W/300W | 500W/1000W |

| Laser wavelength | 1064nm | 1064nm | 1064nm |

| Pulse energy | Max. 1.5mJ | Max. 1.5mJ (single mode), 5mJ | |

| Scanning width | 5-150mm adjustable | 5-100mm adjustable | 5-150mm adjustable |

| Machine weight | 22kg | 60kg | 180kg |

| Cleaning head weight | 1.3kg | 1.3kg | 4.5kg (single mode) 2kg (multiple mode) |

| Fiber length | 5m | 5m | 10m |

| External dimensions | 603*258*481mm | 783*300*784mm | 913*573*881mm |

| Cooling method; | Air cooling | Air cooling | Water cooling |

| Power consumption @25℃ | <500W | <1000W/<1500W | <4000W/<6000W |

| Supply gas pressure | 0.4MPa clean air | 0.4MPa clean air | 0.4MPa clean air |

Cleaned Samples:

The high-power continuous wave (CW) laser cleaning machines are mainly used in rust removal of steel structures, steel plates, ship components; paint removal of steel structures, ships components; oil removal, etc. It is suitable for the refurbishment of marine vessel components, rail transit components, steel structure rust removal, steel structure refurbishment, etc.

2.1 Hand-held CW Water-Cooled Laser Cleaning Machines

| Part number | CL-CW-1500W CL-CW-2000W | CL-CW-3000W |

| Laser power | 1500/200W +/- 2% | 3000W +/- 2% |

| Laser wavelength | 1064nm | 1064nm |

| Working mode | Continuous or modulated | Continuous or modulated |

| Beam quality | M^2 < 1.2 for 1500W M^2 < 1.5 for 2000W | M^2 < 1.5 |

| Machine weight | 170kg | 220kg |

| Fiber length | 10m | 10m |

| External dimensions | 980*420*712mm | 1264*779*1287mm |

| Cooling method | Water cooling | Water cooling |

| Scanning width | 5-150mm adjustable | 5-150mm adjustable |

2.2 Hand-held CW Air-Cooled Laser Cleaning Machines

| Part number | CL-CW-1200W-A CL-CW-1500W-A |

| Laser power | 1200W/1500W |

| Laser wavelength | 1080nm |

| Working mode | Continuous |

| Machine weight | 65kg |

| Fiber length | 10m |

| External dimensions | 715*520*744mm (subject to actual delivery) |

| Cooling method | Air cooling |

| Scanning width | 5mm ~ 150mm, adjustable (F400) 5mm ~ 225mm, adjustable (F600) 5mm ~ 300mm, adjustable (F800) |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616