We specialize in customizing intelligent equipment for laser cutting, welding, marking, cleaning, quenching, cladding and other processes.

We specialize in customizing intelligent equipment for laser cutting, welding, marking, cleaning, quenching, cladding and other processes.

We specialize in customizing:

3D robotic laser cutting machines

3D 5-axis laser cutting machines for metal/non-metal materials

Laser pipe cutting machines for irregular metal parts

High-precision laser cutting machines

Handheld laser cleaning machines

Handheld laser welding machines

3D laser welding systems

3D laser quenching equipment

Precision laser micro-engraving machines for the diamond industry

We also provide customized laser automation solutions and production lines tailored to your specific needs.

Features:

Ideal for rapid cutting of holes, edges, and arcs on irregular workpieces with thicknesses ranging from 0.5-15mm.

Applications:

Equipped with configurable linkage or cooperative positioners, overhead or ground tracks to enable precise and efficient cutting of various materials, shapes, and sizes, including:

Special-shaped pipes & frames

Hot-formed components

Stamped & stretched parts

Metal spheres & vessel heads

3D kitchenware

Automotive molds

Helmets

Engineering plastic molds

Applications:

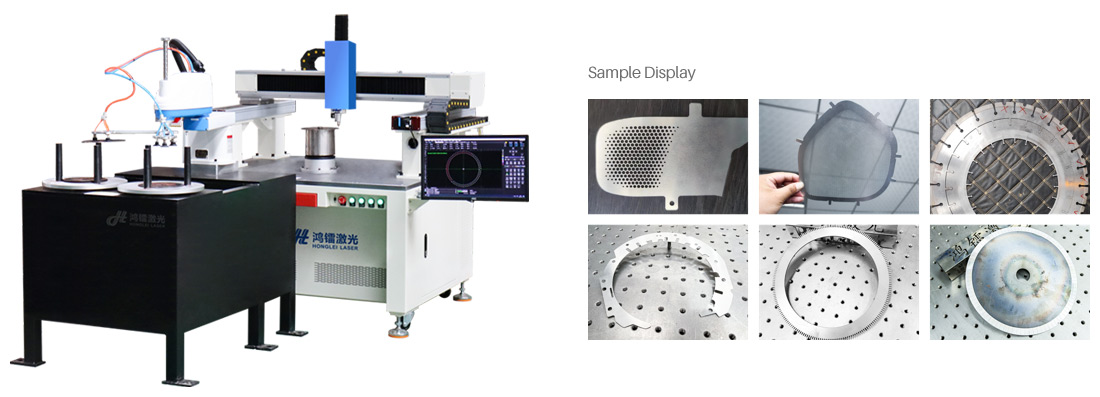

Processing various special-shaped small hardware

Handling ≤1.5m arc-surface hardware (tubes, cones, cylinders)

High-speed precision cutting (holes, slots, hollows, arcs)

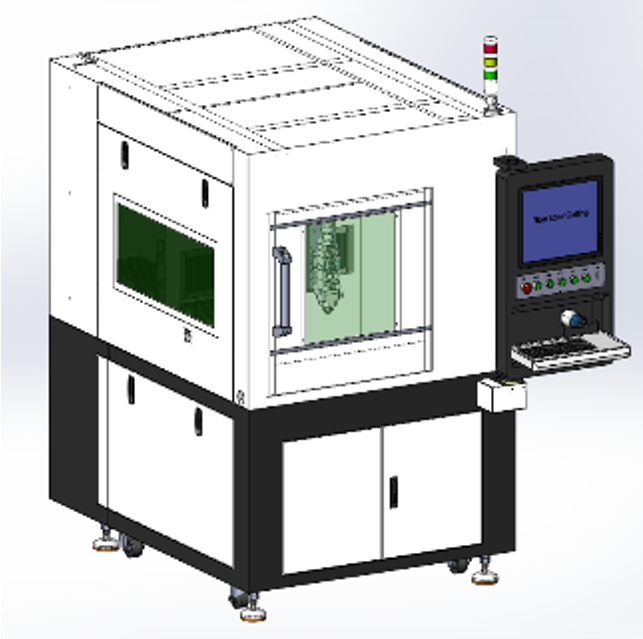

This is a top-quality, super precise, no-deformation high-speed cutting tool! It makes narrow cuts and can handle any shape—perfect for ultra-high-precision work. Great for fast hole and edge cutting on metal sheets under 5mm. Cuts as accurately as ±0.003mm, works over twice as fast as CNC, and maintenance costs are only a third to a quarter of similar CNC punch presses.

This model is an intelligent device developed specifically for high-precision cutting needs of metal saw blades, silicon steel sheets, etc. It deeply integrates high-precision laser cutting technology with a fully automated loading and unloading system, creating an efficient, accurate, and intelligent unmanned solution for saw blade cutting. The equipment adopts an open working platform design, paired with a gantry dual-drive high-rigidity structure, ensuring long-term efficient and stable operation of the equipment.

Applications:

Sapphire, ceramics, silicon, thin metal sheets: precision cutting, drilling, chamfering, surface treatment

Eyewear, electronics, electrical appliances & other precision hardware

Superhard materials (e.g., diamond)

3C, microelectronics: Mg-Al alloy cutting/drilling

Gantry dual-drive structure, ±0.03mm repeat positioning accuracy.

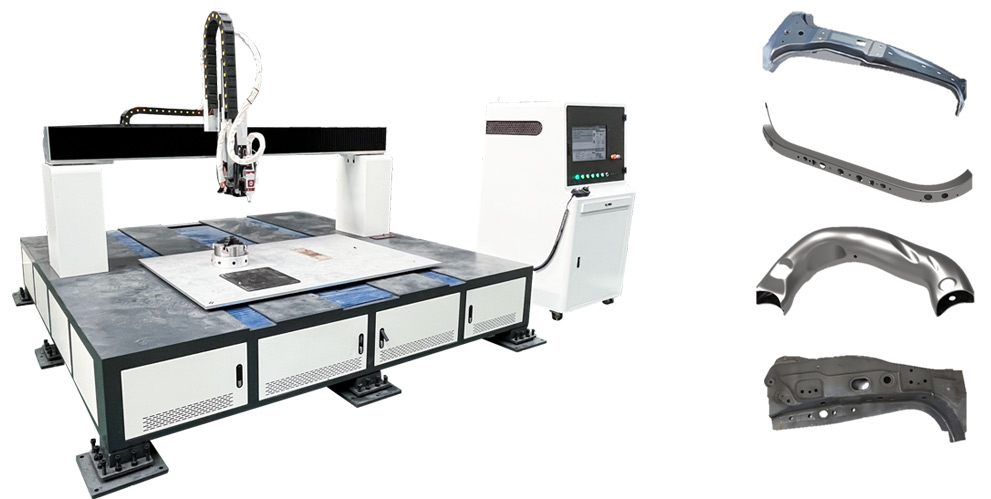

High-performance 5-axis cutting head: N*360° rotation, ±135° swing.

Applications: 3D cutting of thick metal sheets in automotive, marine, machinery, mold, construction, and bridge industries.

Featuring an overhead gantry structure, its 3D head rotates 720° and includes RTCP tool tip following, 5-axis linkage, offline programming, and 3D mapping.

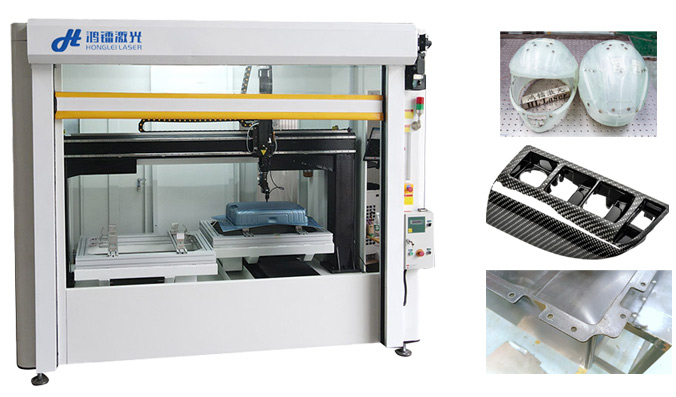

Ideal for high-precision 3D cutting of non-metallic materials, including:

New energy battery separator plates

Luggage

Automotive vacuum-formed parts

Underbody shields

Helmets

Home appliance liners

Human body cup molds

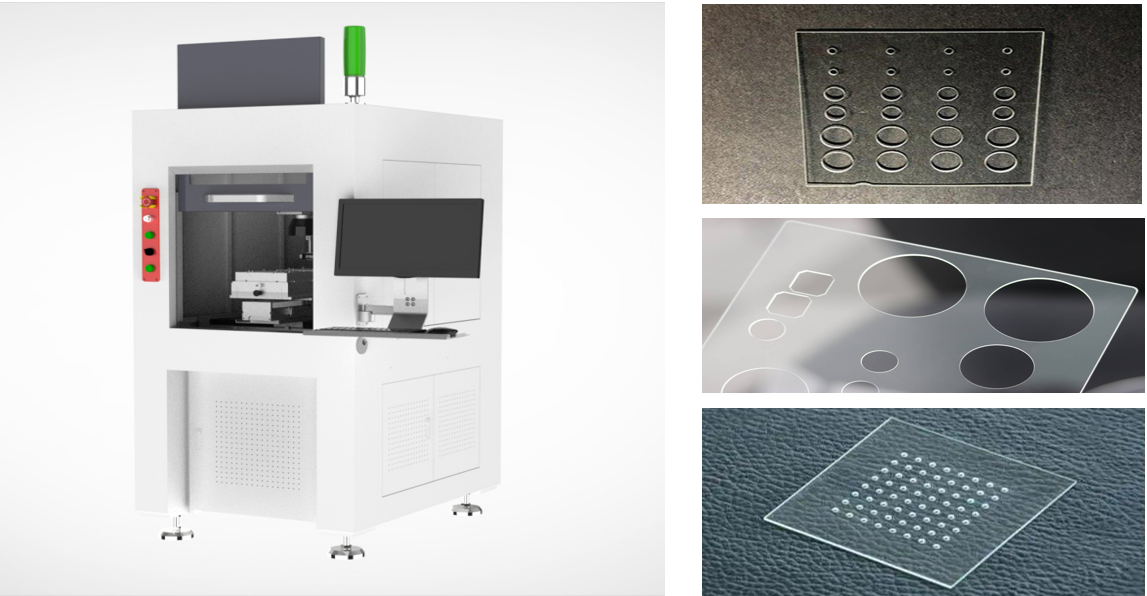

Leveraging ultra-fast laser with Bessel cutting head, it enables non-destructive glass processing (hard and brittle) with μm-level chipping, high efficiency and no taper.

Widely used in 3C electronics, optical lenses, home appliances, bathroom, construction, automotive and photovoltaic sectors.

Non-contact drilling technology ensures high processing speed, precision, minimal edge burrs, superior stability, and zero consumables.

Widely applied in construction, consumer products, medical devices, chemistry, household goods, electronics, and instrumentation industries.

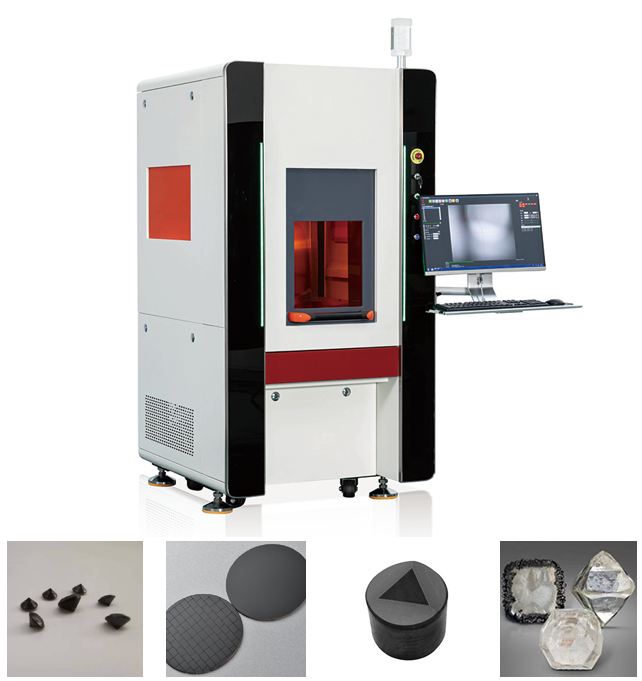

Ultra-precise machining of ultra-hard, ultra-brittle, and difficult-to-process materials.

Applications:

High-melting-point & high-hardness materials: diamond, silicon carbide, superalloys

High-brittle materials: ceramics, silicon wafers

Transparent materials: sapphire, glass-ceramics

It meets the high-precision requirements for processing dimensions and achieves high-quality surface finishing results.

With dual breakthroughs in high precision and efficiency, it demonstrates unique technical adaptability, especially when processing precision structures such as special-shaped air gap slots and micro positioning holes.

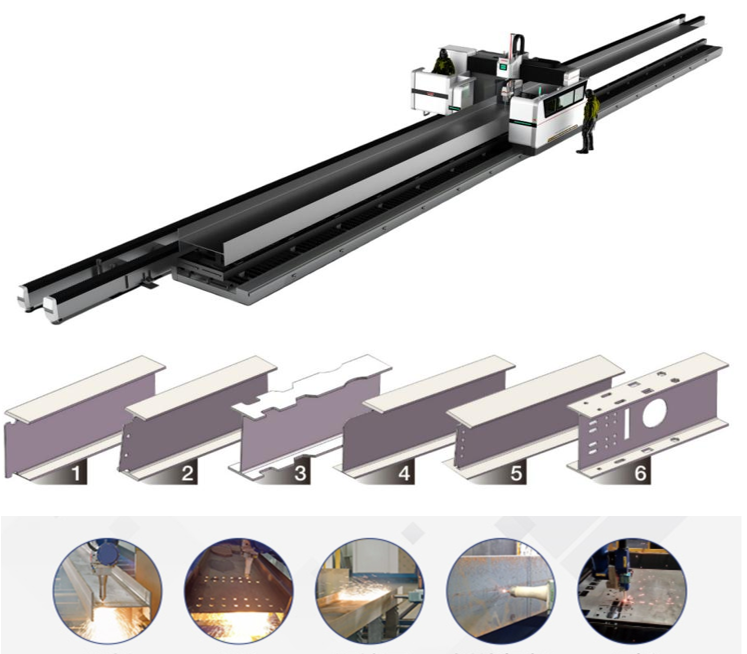

Multi-functional application: capable of cutting H-beams, I-beams, angle steels, channel steels, and flat bevels. One machine serves three purposes.

H-beam cutting range: 100≤height B≤500mm / 180≤width H≤1000mm / length L≤12000mm

Power options: 12000-30000W

Optional bevel processing is available, capable of cutting bevels within 45°. V-type, X-type, Y-type and other different types of bevels can be formed in one go.

Optional cutting sizes: 3015 3020 4015 4020 6015 6020 6025 8025 8032 10025 12025 13030

Power options: 3000-40000W

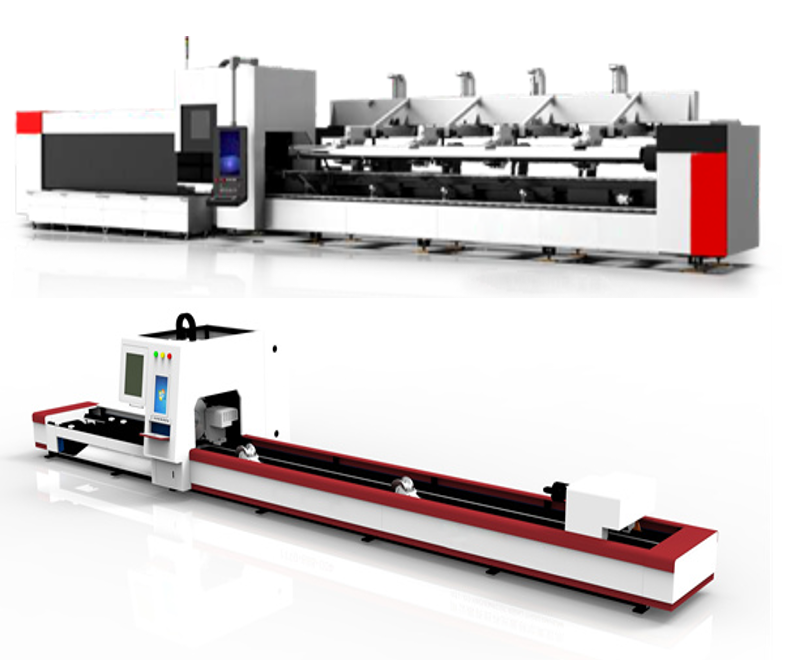

Specialized in cutting various metal pipes such as round pipes, square pipes, rectangular pipes, and elliptical pipes. Optional fully automatic or semi-automatic loading and unloading devices are available.

Optional cutting lengths: 6m 9m 12m; Power options: 1500-12000W

Round pipe processing range: Ф15- Ф660mm; Square pipe processing range: 20-520mm.

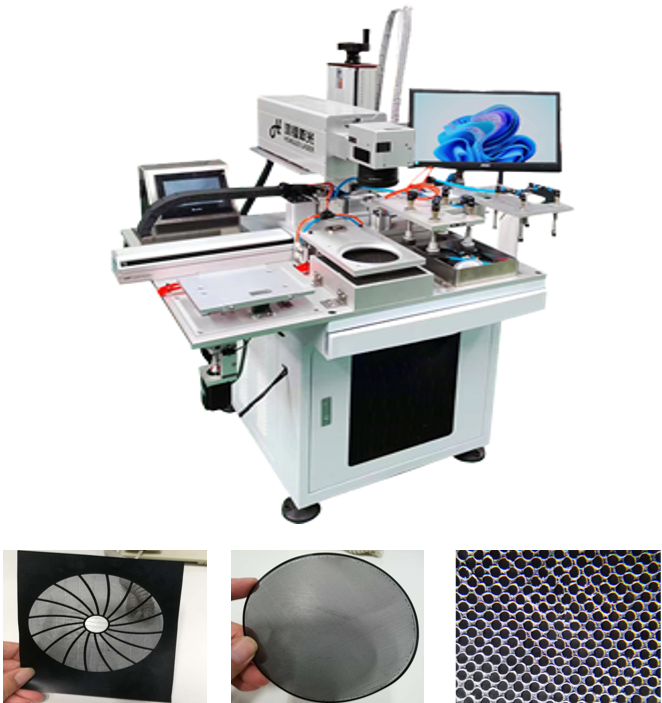

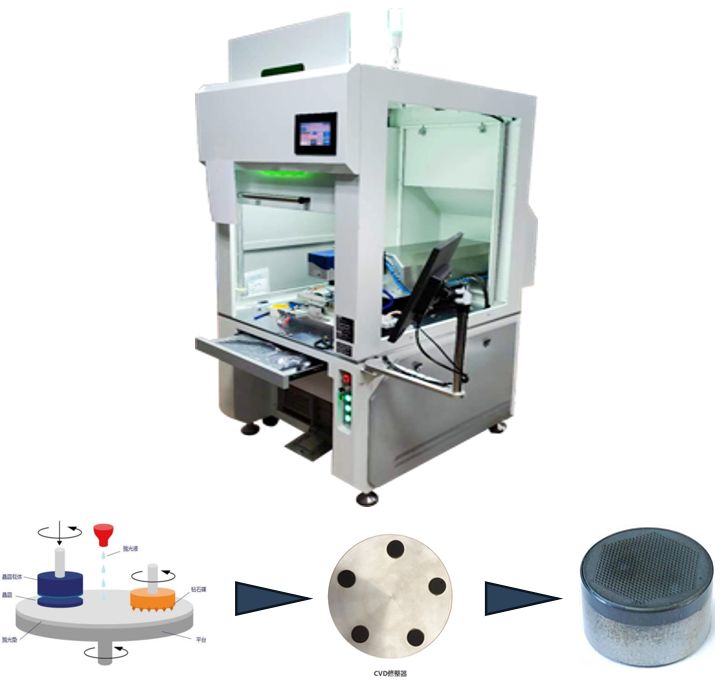

Mainly for dense hole cutting in artificial diamond mesh screens. Also suitable for LOGO marking on high-end electronics, plus fine drilling/engraving on non-metals like crystal, glass and ceramics.

For 3D forming processing of diamond sheets used in CMP diamond discs. It provides precise, consistent and reliable performance for stringent CMP processes, ensuring more stable wear rates and longer service life for CVD dressers.

Suitable for cutting, segmentation, engraving, marking, drilling, grooving, polishing, surface treatment, repair and reshaping.

Perfect welding quality: minimal deformation, high penetration, no burn-through. Supports multiple processes (spot, butt, lap, stack, fillet welding). Suitable for both small-batch multi-variety and mass production.

Widely used in automated welding for production lines, power batteries, kitchenware, bathroom fixtures, auto parts, precision components and hardware.

Water-cooled handheld laser welders handle various metals, with support for single/dual/triple wire feeding. Air-cooled models offer superior beam quality, stable performance, and deep penetration even at low power.

Widely used in sheet metal, advertising signage, kitchenware, stainless steel appliances (stoves, barbecue/dining carts), doors/windows, railings, furniture, lighting, distribution boxes, enclosures, and pipelines.

Suitable for metals like iron, copper, aluminum, gold and silver; non-metals including PC, ABS, PVC, PC+ABS.

Widely used in 3C electronics, auto parts, hardware, building materials, gift processing and other industries.

For Non-Metals:Ideal for marking/cutting on textiles, paper, plastics, wood, leather, glass, PCBs, nameplates, food packaging, electronics, crafts, etc.

Industries Served:3C electronics, automotive, packaging, medical, consumer goods, signage, building materials, arts & crafts.

It is suitable for marking on most metallic and non-metallic materials, and particularly excels in the high-end market requiring ultra-precision processing. It is especially ideal for marking, micro-drilling and surface treatment of materials like food & pharmaceutical packaging, textiles and polymer films. Additionally, it is applicable to high-speed scribing of glass and complex pattern cutting of silicon wafers.

Laser power 1000–3000W, with pulsed or continuous options. Standard 10m fiber (extendable to 20m). Enables chemical/medium/dust/water-free cleaning, removing resin, oil, stains, rust, coatings, paint. Used in aerospace, mold, automotive, food, wastewater, tire/hub, petroleum, pharmaceutical and chemical industries.

Portable design, 28kg total weight – airline/railway shippable. Removes rust, paint, oxidation and other stains from workpieces.

Ideal for cleaning local rust, paint, coatings, oil, oxide films on metal surfaces; a top alternative to workshop grinding tools. Also works on non-metals like ceramics, glass and composites.

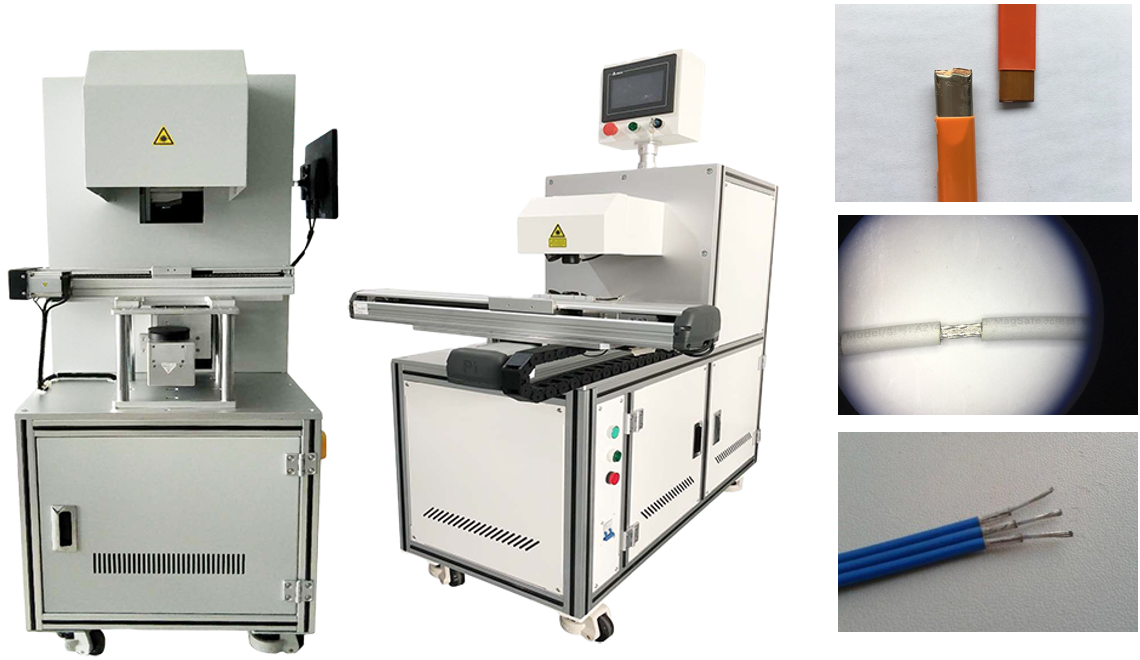

CO₂ laser wire strippers can strip non-metallic outer layers and insulating inner layers; fiber laser wire strippers are capable of stripping metallic shielding layers. Both types are available with dual heads!

It is mainly used for stripping paint films from various enameled wires, transformer pins, inductor coil pins, etc. It also provides services for stripping oxide layers, anodized layers, electrophoretic layers and painted layers from products such as laptop casings and mobile phone casings.

Applicable Materials: Non-metallic materials for wire sheathing and insulation layers, including: PVC (Polyvinyl Chloride), fiberglass, polyester film, fluoropolymers, polyethylene, polyesters, nylon, silicone resin, aluminum foil, Teflon®, and other insulating materials with varying hardness or high-temperature resistance. Paint films on enameled wires, transformer pins, inductor coil pins, etc. Electronic wires such as ultra-fine coaxial cables, antennas, etc.

Mainly used for processing natural diamonds, CVD - grown diamonds, HPHT - grown diamonds, PDC, PCD, graphene, carbon fiber, silicon carbide, gallium nitride, glass and new ceramics.

Capable of processing complex curved surfaces (e.g., gear teeth, mold inner walls) and multi-angle machining, meeting local quenching needs of special-shaped workpieces.

Suitable for laser cladding of simple surfaces like shafts and planes, as well as complex ones such as spheres and curved surfaces.

Capable of cladding shaft surfaces, curved surfaces and special-shaped parts.

Mainly for material surface modification (rollers, gears), product surface repair (rotors, gears) and prototype manufacturing; widely used in coal, metallurgy, offshore platforms, papermaking, civil appliances, automobile, shipbuilding, petroleum and other industries.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616