Laser Cleaning Machine: An Innovative Choice for Modern Surface Cleaning

In the field of industrial cleaning, laser cleaning machines, as a new generation of surface treatment equipment, are gradually becoming the preferred cleaning solution in many industries due to their unique technical advantages. They can efficiently remove rust, grease, paint, primer and other dirt layers from material surfaces, and are easy to operate and automate, bringing a new experience to surface cleaning.

Working Principle of Laser Cleaning Machine

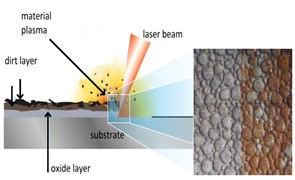

The core working principle of a laser cleaning machine is to use a high-power-density laser beam. When the laser beam comes into contact with the object's surface, the surface absorbs the light and heat of the laser. When the absorbed energy reaches the ablation threshold, the molecular bonds of the surface dirt layer are broken, and then evaporate or peel off from the substrate material.

Since the ablation threshold of the dirt layer is usually lower than that of the substrate material, during the cleaning process, the dirt is removed first, and the substrate material is hardly damaged, thus achieving effective protection of the substrate.

Distinct Advantages of Laser Cleaning Machine

Laser cleaning machines stand out among many cleaning methods due to their numerous significant advantages:

Non-contact cleaning: No direct contact with the surface to be cleaned is required, which greatly reduces damage to the substrate material.

Precise cleaning: Specific areas can be cleaned accurately by preset beam parameters to meet the needs of fine cleaning.

Selective cleaning: Different types of dirt can be removed layer by layer according to the difference in ablation thresholds of different dirt layers.

Efficient cleaning: It has high cleaning efficiency and can complete large-area cleaning work in a short time.

Excellent design: The equipment has a stable and compact structure, with small maintenance workload and low use cost.

Flexible operation: It can be operated by hand by operators or integrated with a mechanical arm to realize automatic cleaning.

Environmental protection and safety: No chemical agents, dry ice and other cleaning media are needed, with few consumables, which is environmentally friendly and safe.

Application Scenarios of Laser Cleaning Machine

Laser cleaning machines have a wide range of applications, covering many fields:

In terms of metal surface cleaning, it can be used to remove local pollutants such as rust, paint, coating, oil stains and oxide films. For example, cleaning the natural oxide film on aluminum alloys before welding, removing the black-gray oxide on battery trays after welding, cleaning the welds of train bogies before non-destructive testing, treating automobile sheet metal parts before renovation, and cleaning steel components such as small holes and grooves that cannot be reached by wire brushes.

At the same time, it is also suitable for surface cleaning of non-metallic substrates such as ceramics, glass and composite materials. In specific applications, it includes various scenarios such as paint removal, oil stain removal, oxide layer removal, dirt and rust layer removal, tire mold cleaning, and weld cleaning.

Product Types and Parameters of Laser Cleaning Machine

There are mainly two types of laser cleaning machines: handheld pulsed laser cleaning machines and handheld continuous laser cleaning machines, each with different parameter characteristics:

Handheld Pulsed Laser Cleaning Machine

The power range of handheld pulsed laser cleaning machines includes 100W, 200W, 300W, 500W, 1000W, etc. Its wavelength is 1064nm, and the scanning width is adjustable between 5-150mm, with slight differences in scanning width among different power models. In terms of cooling methods, small-power models mostly adopt air cooling, while high-power models use water cooling. The weight of the equipment ranges from 22kg (100W) to 180kg (1000W), the weight of the cleaning head is in the range of 1.3kg-4.5kg, and the optical fiber length is 5m-10m.

Handheld Continuous Laser Cleaning Machine

The power range of handheld continuous laser cleaning machines includes 1500W, 2000W, 3000W, etc., and the wavelength is also 1064nm. Its working mode can be switched to continuous or modulated mode, the scanning width is adjustable from 5-150mm, and the cooling method all adopts water cooling. The weight of the equipment is between 170kg-220kg, and the optical fiber length is 10m.

In addition, the laser cleaning machine also has product advantages such as professionally customized laser light sources, light control technology, multiple safety measures, anti-shake technology, more than ten years of process precipitation, and ease of use and durability, which can meet the diverse cleaning needs of different users.

Application Trends of Laser Cleaning Machine

Technical Upgrade Level

In the future, laser cleaning machines will continue to make breakthroughs in technology. On the one hand, the power will continue to increase. Nowadays, there are cleaning lasers with power above 2000 watts. Higher power can achieve faster cleaning speed, meeting the urgent demand for efficient cleaning in large-scale industrial production. At the same time, the pulse width will be further shortened. Short-pulse lasers can release high energy in an extremely short time, remove pollutants more efficiently, and have minimal thermal impact on the substrate material, which is crucial for cleaning high-precision molds and precision electronic components.

On the other hand, the application of multi-wavelength lasers will become more common. Different pollutants have different absorption characteristics for lasers. Multi-wavelength lasers can intelligently select the appropriate wavelength according to the type of pollutants, which greatly improves the pertinence and effect of cleaning. For example, in the field of cultural relics restoration, for complex rust layers and corrosives on bronze ware, impurities can be accurately removed by switching wavelengths, maximizing the protection of the cultural relics themselves. In addition, intelligent technology will be deeply integrated with laser cleaning machines. With the help of artificial intelligence and machine learning algorithms, the equipment can automatically identify the type and distribution of pollutants on the object's surface, and then automatically adjust laser parameters and cleaning paths to improve cleaning efficiency and accuracy.

Functional Expansion Dimension

In terms of functions, laser cleaning machines will develop in a more comprehensive direction. The online cleaning function will be continuously improved. With the advancement of Industry 4.0, the automation level of production lines is getting higher and higher. Laser cleaning machines will be closely integrated with various production equipment to realize real-time cleaning of molds, parts, etc. during the production process, greatly reducing equipment downtime and improving overall production efficiency. For example, in the automobile manufacturing production line, parts being processed can be cleaned online to ensure the smooth progress of subsequent processes.

At the same time, composite cleaning technology will emerge. Laser cleaning will be organically combined with traditional cleaning technologies such as ultrasonic cleaning and dry ice cleaning. First, laser cleaning is used to remove stubborn pollutants, and then other cleaning technologies are used for further fine treatment, giving full play to the advantages of different cleaning methods and improving cleaning quality. In addition, the surface treatment function of laser cleaning machines will be expanded. In addition to cleaning, it can also realize operations such as surface modification and coating preparation. Through laser action, the roughness, hardness, wear resistance and other properties of the material surface can be changed, and the service life of the product can be prolonged.

Market Expansion Direction

From a market perspective, the application range of laser cleaning machines will continue to expand. In the manufacturing industry, in addition to the existing fields such as metal processing and mold manufacturing, the demand in the emerging new energy industry will grow explosively. In lithium battery manufacturing, from cleaning before pole piece coating, surface treatment before welding to cleaning during battery pack assembly, laser cleaning can improve product quality and production efficiency. In the photovoltaic industry, it is used for cleaning the surface of photovoltaic glass, processing frames and brackets, etc., which can effectively improve power generation efficiency and prolong the service life of equipment. In the wind power field, cleaning and maintenance of wind turbine blades, gearboxes and other components can ensure the stable operation of the equipment.

In the field of cultural relics protection, laser cleaning machines, with their non-contact and high-precision characteristics, will be used in more cultural relics restoration projects. Whether it is cleaning metal cultural relics, ceramic cultural relics or ancient building surfaces, they can achieve good cleaning and restoration effects while protecting cultural relics. With the growth of market demand, industry standards will gradually improve, regulating the performance, parameters, cleaning effects and safety requirements of laser cleaning machines, and promoting the healthy and orderly development of the industry.

For more information on our Laser Cleaning Machine, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்