Laser Beam Profiler: A Comprehensive Analysis from Core Principles to Future Trends

As a core tool for accurately analyzing laser characteristics, the laser beam profiler plays an irreplaceable role in modern laser technology applications. From basic principles to practical applications and future development directions, its technological evolution has always been closely linked to the needs of the laser industry.

I. Core Functions and Technical Principles: The Underlying Logic of Accurately Capturing Laser Characteristics

The core value of a laser beam profiler lies in the quantitative analysis of the comprehensive characteristics of laser beams. Its measurement range covers key parameters such as beam shape and propagation characteristics, including beam propagation ratio (M²), waist width (w₀), divergence angle (θₓ, θᵧ), power density distribution, etc., and the measurement results need to comply with international standards such as ISO 11146.

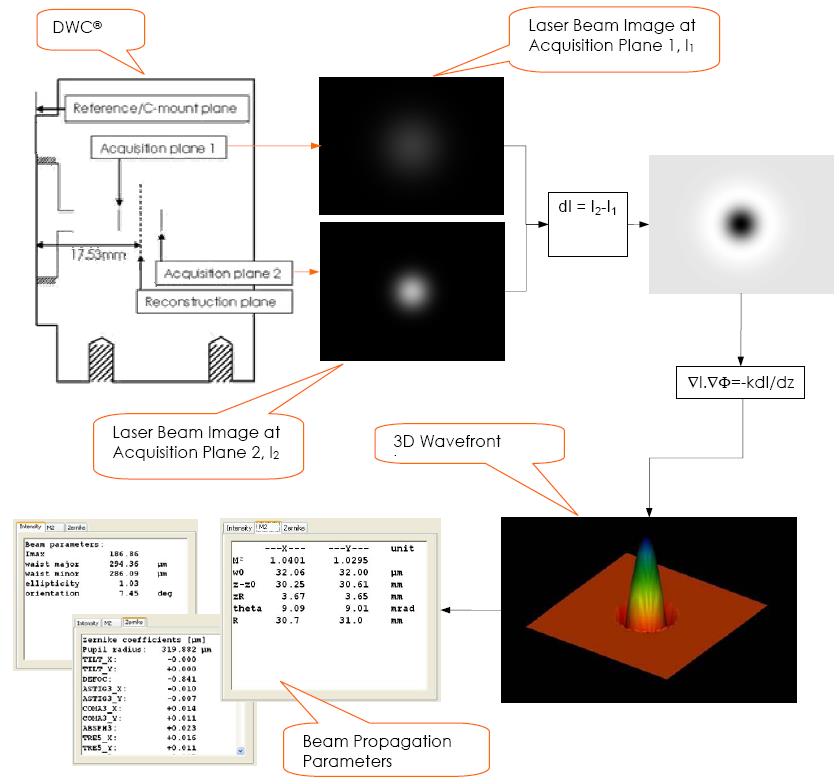

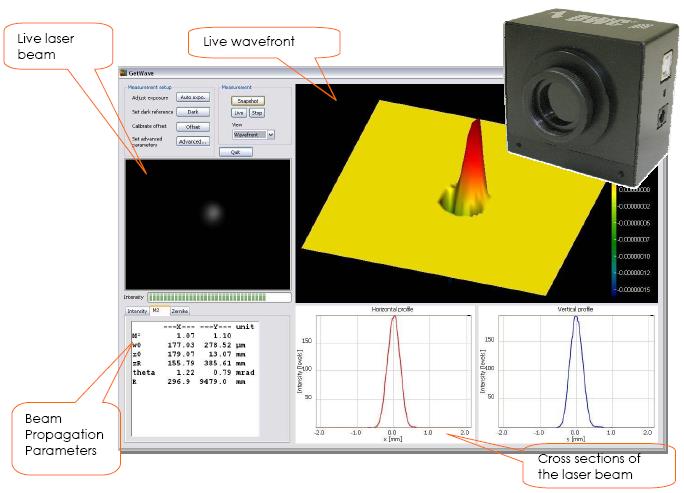

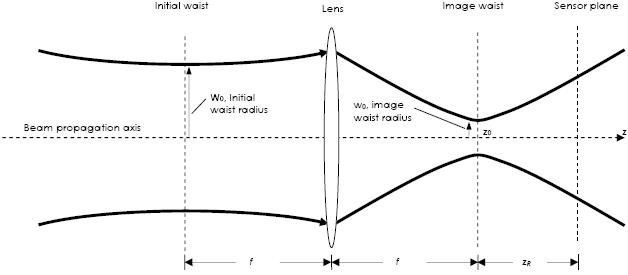

In terms of technical principles, laser beam profilers achieve measurement by capturing beam intensity and wavefront distribution. Taking the Digital Wavefront Camera (DWC) as an example, it obtains beam intensity images on two defocused planes, calculates the wavefront distribution using mathematical algorithms, and then derives beam propagation parameters. The system composition usually includes a sensor module (CCD/CMOS camera or photodetector), optical components (neutral density filters, lenses, etc.), a data processing unit (specialized software), and an interface control part. The software is responsible for image analysis, parameter calculation, and visualization functions, supporting various analysis methods such as Gaussian fitting and second-order moment algorithms.

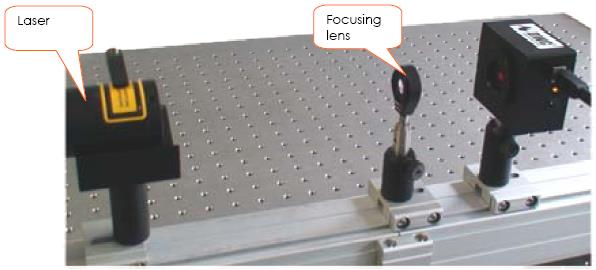

Currently, mainstream technical solutions are divided into two categories: Camera-based profilers, with high-resolution image sensors as the core, have fast response speeds and a spectral response range covering 350-1150nm (some can be extended to 1480-1605nm), suitable for near-field and far-field analysis; Scanning profilers adopt mechanical scanning technology, with a resolution of up to 0.1μm and a wider spectral range (190nm-2500nm), suitable for dynamic monitoring of M² values and divergence angles. In addition, for special scenarios, there are Industrial Laser Monitoring Systems (ILMS) and Line Laser Profiling Systems (LLPS), which are used for measuring high-power lasers and line lasers respectively.

II. Key Applications in Laser Material Processing: From Quality Control to Process Optimization

In the field of laser material processing, laser beam profilers are applied throughout the entire processing process, providing quantitative support for improving processing accuracy and stability.

Ensuring processing accuracy and consistency: By measuring M² values and waist widths, combined with lens focal length, calculate the focused spot size (such as d₀ = M²·4λf/πD₀) to ensure that the spot size meets requirements in high-precision processing such as cutting and drilling (for example, micro-holes need to be controlled within 5-20μm); at the same time, monitor beam ellipticity, and correct directional deviations by adjusting the optical system to avoid uneven width of cutting seams.

Optimizing energy distribution and processing quality: Generate 2D/3D intensity distribution maps to visually display energy distribution, helping to eliminate local hotspots (avoiding material burn-through); track the beam center position and power fluctuations in real-time, trigger the feedback control system to adjust laser output, and ensure the stability of processes such as welding and cladding.

Supporting equipment calibration and parameter debugging: Measure the consistency between the beam propagation axis and the mechanical axis, calibrate the position of optical components to reduce optical path deviations; guide the selection of appropriate focusing lenses through divergence angle and Rayleigh range data to match the absorption characteristics of different materials.

Ensuring safe and reliable high-power processing: Equipped with filters or beam samplers to safely measure the characteristics of high-power beams (kilowatt level); continuously monitor M² values and mode distribution, and timely warn of mode jumps to avoid sudden changes in processing quality.

III. Future Development Trends: Multi-dimensional Breakthroughs in Performance, Intelligence, and Applications

The future development of laser beam profilers will focus on technological upgrading and scenario expansion, showing multi-dimensional breakthrough trends:

Continuous improvement of performance: Measurement accuracy will be further improved to capture more subtle spot characteristics, meeting the needs of high-precision fields such as semiconductor manufacturing; measurement speed will be accelerated to adapt to real-time monitoring of high-power pulsed lasers; the measurement range will be expanded to cover a wider wavelength range (such as deep ultraviolet, mid- and far-infrared) and extreme beam sizes (smaller or larger spots).

Expansion of functional dimensions: Upgrading from 2D measurement to 3D or even multi-dimensional measurement to comprehensively obtain beam spatial information; enhancing the ability to analyze complex beams (such as vortex beams, vector beams) to support research in emerging optical fields.

Intelligence and interconnection: Integrating AI algorithms and machine vision technology to realize automatic identification, analysis, and data processing, reducing human errors; combining 5G and the Internet of Things to support remote monitoring and maintenance, reducing operation and maintenance costs.

Expansion of application scenarios: Deepening applications in emerging fields such as lidar, quantum optics, and 3D printing, and improving cost performance through cost optimization to promote popularization among small and medium-sized enterprises and expand market coverage.

From basic principles to practical applications and future evolution, laser beam profilers have always focused on "accurately quantifying laser characteristics". They are not only witnesses to the development of laser technology but also key forces promoting the laser industry towards higher precision and reliability.

For more information on our Laser Beam Profiler, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்