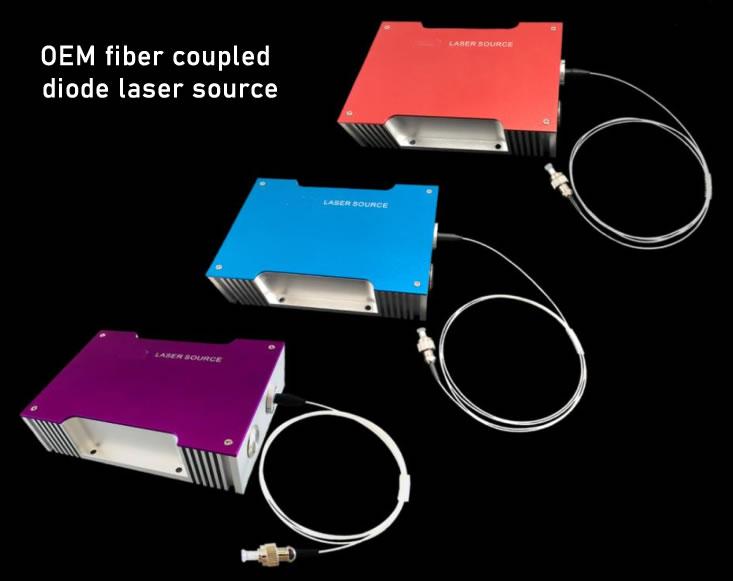

Fiber-Coupled Diode Laser Matrix: Our Multi-Scenario Laser Solutions

In the tech upgrade of industrial manufacturing, scientific research, and medical diagnosis, "precision, adaptability, and stability" are core demands for laser equipment. We specialize in laser technology and offer a fiber-coupled diode laser system with five core series (STW, STCX, STK, STC, STR). Covering 375nm~1920nm wavelengths and 1mW~6000W power, this system delivers turnkey solutions plus customized services, making us a global customer favorite.

I. Core Series Overview: From Low-Power Precision to High-Power Industrial Use

Our laser series target distinct power needs and scenarios, forming a comprehensive matrix for lab micro-operations to heavy industrial high-load processing.

(I) STW Series: Multi-Wavelength Low-Power "All-Rounder"

Wavelength & Fiber Flexibility: 375nm (UV) ~1920nm (near-IR); supports SMF (3um~5um core), MMF (105um~1000um core), and PMF (3um~9um core). E.g., 405nm SMF for bio-fluorescence excitation; 1550nm PMF for optical communication testing.

Integrated Design: Turnkey system with laser module, LD driver, and TEC cooling; 90V~240V wide voltage input; TTL/analog modulation for millisecond on-off control.

Stability Assurance: 72-hour aging test before delivery; <1% power fluctuation; 10,000+ hours lifespan. E.g., 375nm 100mW MMF (STW-LS-375-100m-M) maintains <0.01mm seam width in precision lithography.

(II) STCX Series: Medium-High Power Industrial "Backbone"

Divided into DDLM (100~1000W) and DDLF (2000~6000W) for metal cutting, welding, and surface treatment:

Power & Wavelength Match: 915nm/976nm (high metal absorption); 1000W for aluminum thin-plate welding; 6000W for >10mm thick steel cutting; 10%~100% power adjustability; <0.1mm HAZ.

Industrial Hardware: QBH high-power connector; 10~20m fiber length; graded cooling (air for 100~300W, water for >500W); 5~40℃ stable operation.

Compliance: EU CE certified; 650nm red indicator for positioning; 220V/380V compatible. E.g., 3000W DDLF (STCX-DDLF-3000) runs 8hrs non-stop for new energy vehicle frame welding.

(III) STK Series: Lightweight Customizable "Flexible Solution"

1W~400W for 3D printing, plastic welding, and lithium battery manufacturing:

Size & Cooling: S/M/L chassis (min. 260x360x125mm, <15kg); air cooling (<300W) or water cooling (>300W). E.g., STK-DS3-2 (air-cooled) for small electronics welding.

Smart Control: Touchscreen + RS232 interface for PLC/upper-computer integration; up to 20kHz modulation; 20μs~999ms pulse width.

Global Service: Sold in 70+ countries; customized models (e.g., 405nm 5W for SEA 3C factories with 5%~80% humidity resistance).

(IV) STC & STR Series: "Special Solutions" for Extreme Scenarios

STC Series: Low-power high-precision (A: 444~980nm <50W; B: 1064~1908nm <50W) and high-power integrated (H: 50~300W); LED current display; for research pumping/medical diagnosis. E.g., 808nm 300W (STC-FC-W-808H) for LIBS analysis.

STR Series: 50~6000W industrial flagship; >45% electro-optical efficiency; low maintenance; for thick material cutting/cladding; handheld + remote control. E.g., 6000W (STR-A6000D) controls 0.5~5mm cladding thickness for machinery repair.

II. Core Technical Advantages

Our laser systems excel in four key areas to fit diverse scenarios:

Wide Wavelength Coverage: 375nm~1920nm (UV for sapphire drilling; visible light for metal thin-plate cutting; near-IR for thick material welding).

Stable Full-Power Output: <±3% fluctuation (1mW~50mW); 10%~100% adjustability (1W~500W); ≤3% instability (1000W~6000W). E.g., 6000W cuts 20mm steel at 1.5m/min.

High Integration: All-in-one design (no extra power for STW); overcurrent/overtemperature protection; 6-month filter replacement for water-cooled models.

Customization: Non-standard wavelengths (e.g., 1920nm 400mW MMF); adjustable fiber specs; industry-specific designs (aseptic for medical, dust-proof for industrial).

III. Global Applications

Our systems serve 70+ countries (10M+ units sold) across fields:

Industrial Manufacturing: High-power models replace plasma cutting (30% narrower seams, 50% less waste); medium-power for plastic welding (20% stronger joints).

Scientific Research: UV/near-IR for nanomaterial prep/graphene etching; low-power visible light for cell imaging.

Medical Care: 635nm~660nm red light for endoscopy/blood flow monitoring; 980nm 5W for dental implant cutting.

New Energy & 3C: 3000W for battery pack welding; 405nm 5W for phone chip QR marking.

IV. Conclusion

From 375nm UV precision to 6000W industrial processing, our five-series matrix delivers "full-wavelength, full-power, full-scenario" solutions. Backed by tech stability and customer-centric customization, we drive industry upgrades amid global manufacturing’s shift to "high precision, low carbon, intelligence." We’ll keep advancing laser tech to create more value for global customers.

For more information on our Fiber Coupled Diode Laser Systems, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்