Our 1064nm 3-Axis Laser Glass Cutting Machine: An Efficient Solution for Precision Machining

In the field of glass processing, precision, high-efficiency, and low-damage cutting technology has always been the core goal pursued by the industry. Our SHR-LGPS-1064-60-10 3-axis laser glass cutting machine integrates cutting-edge core technologies with user-friendly design, providing a professional solution that combines stability and cost-effectiveness for brittle material processing. It is widely applicable to various special-shaped glass processing scenarios, has achieved mature implementation in multiple industries, and demonstrates strong development potential in the booming market.

Core Technologies and Advantages

Enhanced Cutting Quality with Dual Core Technologies

The machine is equipped with Perfect Score Technology (PST) and Particle Swarm Optimization (PSO) algorithm. These two core technologies work synergistically to achieve high-speed cutting of special-shaped glass. The chipping amount can be controlled within 10μm, far exceeding the precision standards of traditional cutting processes. This maximizes the integrity of the glass edge and reduces subsequent grinding procedures. Additionally, the machine features a highly integrated database that can quickly match optimal processing parameters, eliminating the need for repeated adjustments and significantly improving production efficiency.

Seamless Automation Adaptation and Flexible Expansion

Equipped with a PLC interactive system, it can easily connect to upstream and downstream stations of automated production lines, realizing seamless integration of the processing workflow. It supports two cutting modes: fixed beam and moving beam. Combined with a 4-axis control port and rotary cutting signal output function, it can meet diverse processing needs such as flat cutting and special-shaped cutting. The software system is compatible with CAD file import and direct drawing editing, and can also automatically optimize processing paths and support custom editing, ensuring convenient operation and high flexibility.

Stable and Reliable Design for Reduced Comprehensive Costs

It adopts a marble workbench, which offers excellent stability and shock resistance, laying a solid foundation for high-precision processing. The machine operates within a temperature range of 20°C to 30°C, and is equipped with a water-cooling heat dissipation system to ensure stability during long-term continuous operation. Through precise parameter control and efficient processing procedures, it not only reduces material waste but also lowers costs related to manual adjustment and subsequent processing, achieving the production goal of "cost reduction and efficiency improvement".

Industry Application Cases: Practical Verification of Technical Value

Consumer Electronics Sector: Sapphire Cover Glass Cutting Yield Rises to 99%

A high-end smart watch manufacturer needed to process 2.9mm-thick special-shaped sapphire glass covers. With a hardness of 9 Mohs (second only to diamond), traditional processes caused chipping exceeding 50μm due to mechanical stress, resulting in a yield rate of only 60% and requiring multiple polishing procedures. After introducing our 1064nm laser cutting machine, non-contact cutting was achieved through picosecond cold processing technology and PSO path optimization. The chipping amount was controlled within 5μm, and the special-shaped contour was formed in one cut without secondary processing. The CCD visual positioning system equipped on the machine controlled the cutting error within ±0.01mm. Combined with the automated dual-station design, the single-shift production capacity increased by 3 times, the yield rate soared to 99%, and the annual processing cost was reduced by over 2 million yuan.

Automotive Electronics Sector: "Zero-Damage" Processing of Curved HUD Glass

A new energy vehicle enterprise faced two major challenges in processing curved HUD glass: traditional waterjet cutting reduced light transmittance by 3%, and the cutting precision of curved contours was less than ±0.1mm. After adopting our machine, non-contact cutting was realized by virtue of the precise focusing of 1064nm laser and dynamic stress control technology, completely avoiding damage to the optical properties of the material. The machine's 4-axis linkage system adapts to changes in curved surface curvature, with a cutting speed of 300mm/s and a pitch precision of ±0.5μm, perfectly meeting the dual requirements of light transmittance and precision for in-vehicle display devices. Currently, this machine has been integrated into the mass production line of the automobile manufacturer, processing over 500,000 pieces of HUD glass annually and reducing waste loss by 3 million yuan.

Architectural Decoration Sector: Construction Period for Large-Scale Artistic Curtain Walls Reduced by 50%

A high-end hotel customized 12mm-thick ultra-white glass special-shaped artistic curtain walls, requiring 0.5mm fine texture cutting and dense micro-hole processing. The traditional CNC grinding process required a construction period of 60 days, and cracks were prone to occur at the edges of micro-holes. Our laser cutting machine achieved high-speed hole drilling at 20mm/s through high-power 60W laser output and path optimization algorithm, with a hole position precision of ±0.1mm, fully meeting the airtightness requirements of LEED certification. The machine supports a processing area of 400mm×600mm (customizable for expansion). Combined with the full-plate cutting solution, 120 originally scattered components were integrated into 10 large-sized processed parts, shortening the construction period to 30 days and reducing the comprehensive construction cost by 25%.

Market Prospects: A Growing Blue Ocean Driven by Policies and Demand

Continuous Expansion of Global Market Scale and Broad Space for Laser Replacement

Laser glass cutting is in the explosive stage of technological replacement for traditional processes. In 2024, the global market revenue of float glass cutting machines reached 13.05 billion yuan, and it is expected to approach 18.05 billion yuan by 2031, with a compound annual growth rate of 4.7% from 2025 to 2031. Among them, the growth rate of high-precision laser cutting equipment far exceeds the industry average. In the automotive glass segment alone, the global laser cutting equipment market scale will reach 1.5 billion US dollars by 2025, with China becoming the core growth engine with a market share of over 40%. Currently, the penetration rate of laser cutting in glass processing is still in the initial stage. Compared with the pain points of traditional mechanical cutting such as low efficiency, high damage, and poor adaptability, laser solutions represented by our equipment are accelerating the capture of high-end markets such as consumer electronics and automotive electronics, presenting considerable replacement potential.

Explosive Demand in Multiple Sectors and Competitive Barriers Built by Technical Adaptability

The demand upgrade in three core sectors provides a clear growth path for the equipment: In the automotive electronics sector, the global penetration rate of new energy vehicles is expected to reach 45% by 2025. Smart cockpits are driving the development of central control screens, HUD glass, and sunroof glass towards larger sizes, curved surfaces, and special shapes. Traditional processes can hardly meet the processing needs, while the 4-axis linkage and curved surface adaptation capabilities of our equipment can accurately match the mass production needs of automobile manufacturers. In the semiconductor and consumer electronics sector, components such as camera protection films and sensor covers are developing towards thinner sizes (below 0.2mm) and higher hardness (sapphire). The chipping control within 10μm and picosecond cold processing technology of our equipment can perfectly solve the problems of cracks and optical performance damage caused by traditional cutting. In the architectural decoration sector, the growing demand for personalized ultra-white glass and artistic glass makes the customizable processing area and fine texture cutting capabilities of our equipment align with the efficiency and quality requirements of high-end buildings.

Technological Iteration and Policy Support to Open Long-Term Growth Space

The improvement of laser power (capable of cutting 17mm-thick glass) and the development of automated integration technology continue to expand the application boundaries of laser cutting. The highly integrated database and PLC interactive system of our equipment have been pre-adapted to the upgrading direction of intelligent manufacturing. At the same time, the global pursuit of green manufacturing is promoting the transformation of processing processes towards low energy consumption and low pollution. Compared with traditional mechanical cutting, laser cutting reduces material waste by more than 30% and produces no dust pollution, complying with the environmental protection policy orientation of industries in various countries. In the future, with the release of glass demand in emerging scenarios such as 5G base stations and smart wearable devices, the high precision and flexible adaptability of our equipment will become more prominent, and it is expected to establish a first-mover advantage in the segmented market.

Key Technical Parameters

•Laser Performance: Adopts 1064nm wavelength laser, with an output power of 60W/60kHz, a pulse width of 10ps, an adjustable repetition frequency range of 50-300kHz, and a maximum cutting speed of 300mm/s.

•Processing Capacity: Maximum cutting thickness of 6mm, processing precision less than 5μm, pitch precision of ±0.5μm, processing resolution of 1μm, supporting layered cutting of 0.03-36mm glass.

•Adaptable Specifications: Processing area of 400mm×600mm (customizable), supporting 4-axis control to meet processing needs of different sizes and shapes.

•Operating Conditions: Input voltage of AC220V/AC110V (50Hz/60Hz), working environment humidity below 60%, dust content less than 0.20mg/m³, and no oil mist interference.

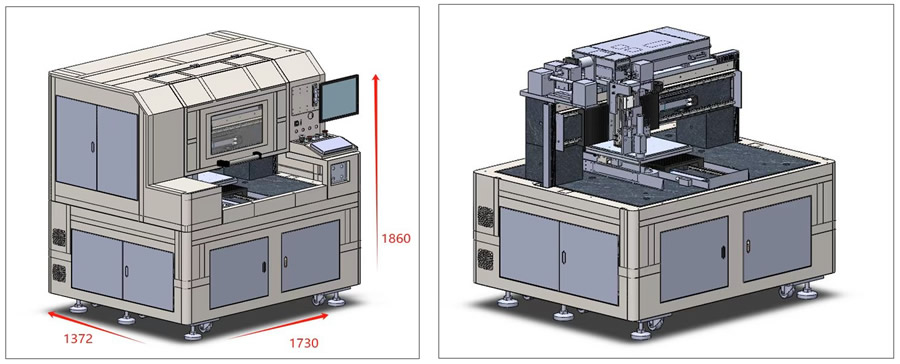

•Equipment Specifications: Weight of approximately 70kg, equipped with RS-232/Ethernet control interface, and 3m-long cables for flexible layout of production space.

Applicable Scenarios and Value-Added Services

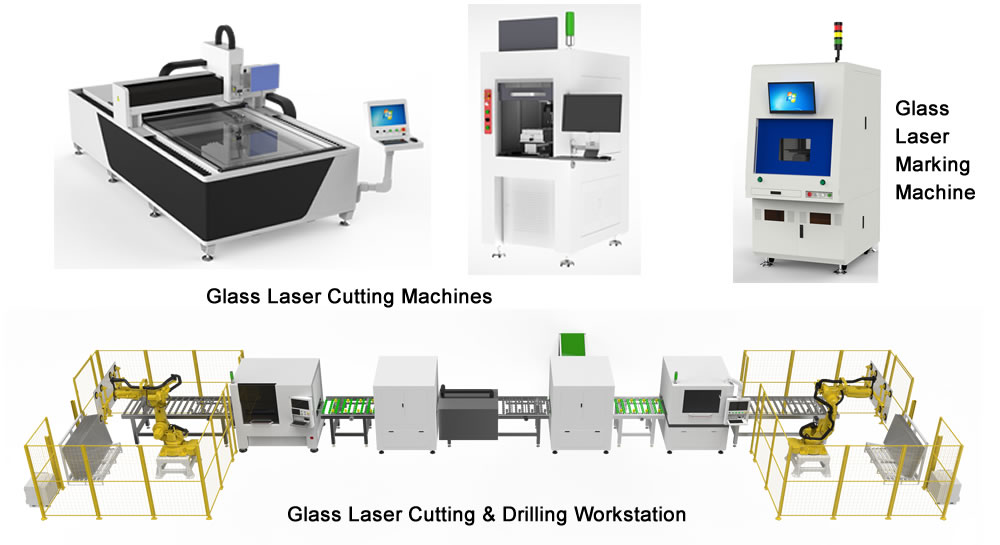

This machine is specially designed for glass processing, especially suitable for cutting brittle materials and precision glass components. It is widely used in special-shaped processing scenarios in industries such as electronic glass, optical glass, and decorative glass. We provide personalized parameter customization services, which can adjust the equipment configuration according to the specific processing needs of customers. In addition, we also offer free sample testing services; customers can submit samples for targeted cutting tests to intuitively experience the processing effect. For more process details, you can view the official supporting videos or consult about other related equipment such as glass laser marking machines and laser cutting and drilling workstations.

For more information on our Laser Glass Cutting Machine, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்