Market and Technological Development of Glass Laser Cutting

With the rapid development of consumer electronics, automobile manufacturing, photovoltaic industry and architectural decoration field, the processing demand for glass materials is increasing day by day. The traditional glass cutting process has been unable to meet the requirements of modern industry for high quality and high efficiency due to low efficiency, limited precision and easy to produce edge cracks. With non-contact processing, high precision, high flexibility and high stability, laser cutting technology has rapidly become an important solution in the field of glass cutting, and the market scale continues to expand.

According to industry statistics, the global glass laser cutting market is growing at a high rate, driven by the demand for consumer electronics (e.g., smartphones, tablet PCs, wearable device screens). Especially in the processing of ultra-thin glass and complex shapes, laser cutting technology shows the incomparable advantages of traditional processes, and has become a key tool to promote the upgrading of the new generation of manufacturing.

1. Glass laser cutting technology principle

Glass is a hard and brittle material, the traditional cutting method often produces micro-cracks due to stress concentration, while the laser cutting technology through the thermal effect or optical nonlinear effect, can achieve high precision and low damage cutting. There are two main technical principles:

1) Thermal stress cutting

The laser beam rapidly heats the glass surface through a focused spot of high energy, causing it to expand in the heated area. At the same time, a localized temperature gradient is formed by water or air cooling, inducing stresses that fracture the glass along a predetermined path. This method is suitable for glass materials with large thickness.

2) Non-linear effect cutting

Using ultrashort pulse laser (such as picosecond, femtosecond laser) focused on the inside of the glass, through the nonlinear absorption of high-intensity light to produce micro-bursting effect, the formation of micro-crack network, and then along the crack to achieve precise cutting. This technology is suitable for ultra-thin glass or high-precision processing, especially in the field of flexible screen is widely used.

2. Lasers mainly used for glass cutting

Glass laser cutting requires high performance of the laser, which usually needs high power density, short pulse width and high beam quality. The following are common types of lasers:

(1) CO₂ laser

Suitable for traditional thermal stress cutting, mainly used for thick glass cutting. CO₂ lasers are less costly, but less suitable for scenarios requiring high precision and surface quality.

2)Ultraviolet laser

With short wavelength, high absorption characteristics of the ultraviolet laser can realize cold processing, reduce the impact of thermal effects, is the ideal choice for cutting high fine electronic glass.

3)Ultra-fast lasers

Including femtosecond laser and picosecond laser, its extremely short pulse width can produce non-linear effect inside the glass, realizing high-quality and high-precision cutting. It is especially suitable for high-end application scenarios such as ultra-thin glass and flexible screen.

3. Beam delivery system and cutting head

Efficient beam transmission and cutting head design is the core of glass laser cutting system, which directly affects cutting accuracy and stability.

(1) Beam delivery system

The laser is transmitted to the processing area through optical fiber or reflector, and fiber laser has become the mainstream choice due to its strong flexibility and stable energy. In addition, the precision of the focusing mirror group directly determines the spot size and energy distribution.

2) Cutting head

Cutting head includes focusing mirror, cooling module and auxiliary gas nozzle and other parts. The cooling system ensures that heat is dissipated in a timely manner, and auxiliary gases (such as nitrogen or air) are used to remove processing debris and prevent crack expansion. Some high-end cutting head also integrated sensors, real-time monitoring of the focus position and cutting quality.

4. Glass laser cutting process

Glass laser cutting process is mainly divided into the following steps:

(1) Pattern design and path planning

Design the cutting path according to product requirements and program it in the CNC system.

2) Focus adjustment

Adjust the laser focus position to maximize the spot energy to concentrate on the glass surface or internal target area.

3)Cutting process

Select appropriate laser parameters (such as power, pulse width, scanning speed, etc.) according to the cutting thickness and material, and control the cutting quality with cooling or auxiliary gas.

4)Post-processing

After cutting, the edges can be ground or strengthened as needed to improve mechanical strength and optical properties.

5. Cutting quality evaluation

The quality evaluation indexes of laser cut glass mainly include the following aspects:

(1) Cutting edge smoothness

High-quality cutting should have smooth edges without cracks and burrs.

2) Dimensional accuracy

The cutting accuracy should be controlled within the design tolerance, especially in the field of consumer electronics, the precision requirement usually reaches micron level.

3) Heat-affected zone size

The heat affected zone should be as small as possible to avoid affecting the mechanical properties and optical transmittance of the glass.

4) Crack control

If micro-cracks are generated during the cutting process, the strength of the glass will be seriously reduced, so it is necessary to optimize the laser parameters or use auxiliary processes to reduce cracks.

6. Conclusions

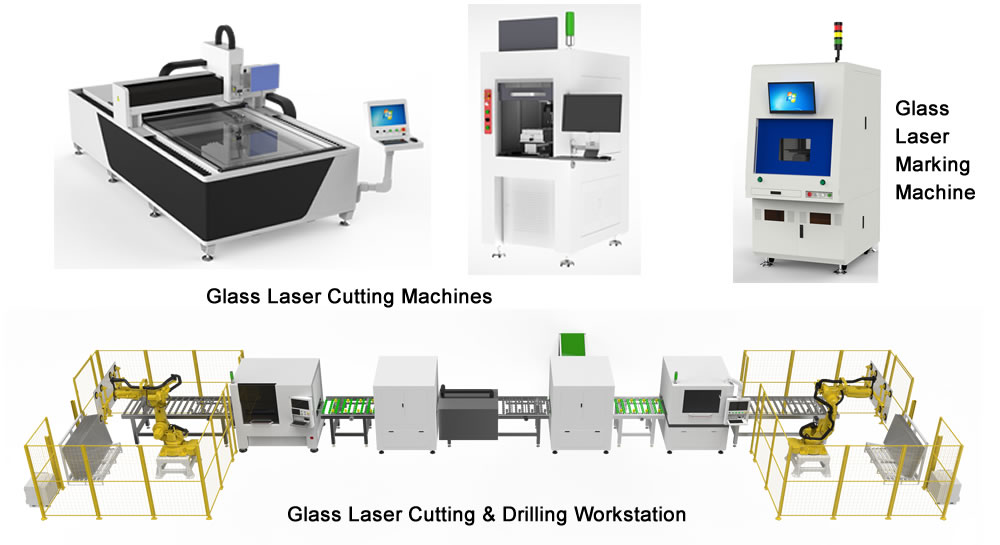

Glass laser cutting technology is gradually replacing the traditional cutting methods, becoming the mainstream choice in the field of modern glass machining. With the advancement of laser technology and the popularization of intelligent control system, its application scope will be further expanded. In the future, laser cutting equipment that combines artificial intelligence and automated production lines will certainly provide more possibilities for the development of Industry 4.0 and bring new opportunities for the high-end manufacturing industry.

For more information on laser glass cutting machines, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்