Advanced VCSEL Laser Diode Technology and Diverse Applications

Vertical-Cavity Surface-Emitting Lasers (VCSELs), a core semiconductor laser technology, are pivotal enablers for cutting-edge fields like AI and IoT, valued for their unique structural advantages and broad applicability. Backed by deep technical expertise, our VCSEL portfolio covers multi-wavelength and multi-power solutions, serving industrial, medical, and consumer electronics sectors.

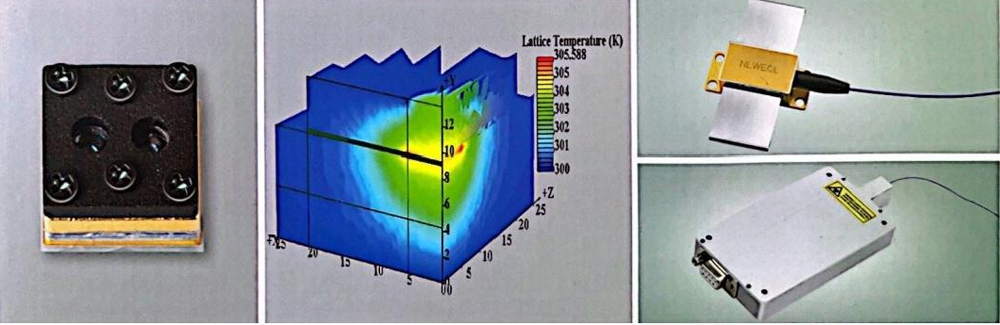

Our VCSEL technology centers on GaAs-based epitaxial design, leveraging proprietary optical design software and process know-how to meet multi-dimensional requirements. Customizable epitaxial structures and device parameters (e.g., ±10nm wavelength control via DBR thickness adjustment) address stringent spectral matching requirements. Key processes—ICP etching (nanometer precision), wet oxidation (optimizing beam divergence to 10°), and BCB planarization—ensure optical stability and mode control.

(1) Full-Waveband Coverage and Power Flexibility

Visible Light: Blue/green/orange modules (500mW+ power, near-diffraction-limited beam quality) enable laser display and bio-fluorescence applications. Example: 650nm red modules (linewidth <100MHz) for stage lighting and medical aesthetics.

Near-Infrared Portfolio:

Low-Power Precision: 790nm single-mode VCSELs (SSK-790 series) deliver 1.2–1.5mW at 3.5mA, with ±0.06nm/°C wavelength stability via TEC control, ideal for atomic clocks and magnetometers.

Industrial-Grade High Power: 808nm VCSEL arrays (100W peak, microchannel water cooling) enable 12mm metal cutting in QCW mode.

Ultra-High Pulse Power: 940nm double-junction VCSELs (400W peak, nanosecond pulses) support LiDAR with adjustable 60°×45°–120°×90° beam angles.

(2) High-Precision Integration and Environmental Robustness

Smart Thermal Control: TO46/TO56 packages integrate TEC (70°C max delta, 0.4W cooling) and NTC sensors for ±0.1°C temperature stability, ensuring <5% power drift in high-temperature industrial settings.

Anti-Interference Design: Surface grating achieves 25dB polarization extinction; automotive-grade 850nm VCSELs (AEC-Q102 certified) withstand ±8kV ESD via EMI shielding.

Longevity Design: 50,000+ hour lifespan, <3% power degradation after 1,000-hour CW aging tests, suited for 24/7 industrial operations.

(3) Modular Design and Customization

300+ Standard SKUs: 20+ packages (e.g., 2.0×1.6mm 2016AIN for compact devices, 7060CuAg with integrated heat sinks).

Custom Solutions: Aerospace-qualified 1064nm modules (-40°C to 125°C stability) and medical 940nm annular beam modules with 360° uniform illumination.

II. Application Scenarios

1.Intelligent Sensing and LiDAR: 850nm/940nm modules for 3D ToF (smart vacuum cleaners, AR/VR) and 808nm 150W pulsed VCSELs for automotive LiDAR.

2.Industrial and Medical: 808nm CW modules (300W) for metal processing; 660nm red light for dermatology, 940nm IR for non-contact thermometry.

3.Consumer Electronics: 850nm line arrays (130mW) for 3D facial recognition; 6G/10G VCSELs for data center optical interconnects.

4.Scientific Research and Measurement: 790nm single-mode VCSELs (70MHz linewidth) for atomic sensing in high-temperature environments (up to 90°C chip temp).

III. Industry Advantages

One-Stop Customization: From epitaxy to packaging, with conduction/water-cooled QCW modules for extreme environments.

Certifications: ISO9001, IATF16949, AEC-Q102 certified for automotive and industrial use.

IV. Future Directions

R&D focuses on visible-light VCSELs (500mW+ green modules) and single-mode long-wavelength VCSELs (1060nm+), targeting autonomous driving and biomedical imaging.

For more information on our VCSEL laser diodes, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்