Exploring Our High-Power Diode Laser Devices: Core Light Sources Empowering Intelligent Manufacturin

In fields such as laser pumping, industrial precision machining, medical aesthetics, and intelligent sensing, high-power diode laser chips, bars, and stacks have become core foundational components. As a professional manufacturer deeply engaged in the laser industry, we have leveraged mature epitaxial growth, chip etching, and packaging processes to develop a full range of diode laser products covering the 0.75μm-1.06μm wavelength band. With diversified power levels, packaging formats, and customized solutions, we deliver high-performance light source solutions for diverse scenarios.

I. Product Matrix: From Basic Chips to Integrated Stacks

Our diode laser product portfolio features a tiered structure, ranging from single-emitter chips to multi-unit stacked assemblies, catering to the full spectrum of needs from laboratory research to industrial mass production.

1. Core Basic Devices: Single-Emitter Chips and Bars

Single-emitter laser chips serve as the fundamental building blocks for high-power laser modules. Our BC series chips cover mainstream wavelengths such as 915nm and 976nm, with output power ranging from 25W to 30W. Operating in continuous wave (CW) mode, they offer a fast-axis divergence angle of 55°, a slow-axis divergence angle of 9.5°, TE polarization up to 97%, electro-optical conversion efficiency exceeding 62%, and a slope efficiency of 1.1-1.15W/A. These chips are ideal for low-power precision pumping and sensing applications.

High-power diode bars achieve power scaling through multi-emitter integration. Our BB series bars are available in wavelengths like 808nm and 940nm. Among them, the 940nm band products boast a maximum output power of 700W, 34 emitters, an 80% fill factor, a fast-axis divergence angle ≤55°, a slow-axis divergence angle ≤8.5°, and a spectral width (FWHM) controllable within 5nm. With a wavelength temperature coefficient of 0.3nm/℃, they maintain stable performance in the complex temperature-varying environments of industrial processing, and are widely used in medium-to-high power scenarios such as metal welding and laser cladding.

2. Specialized Devices: VCSEL Chips and Customized Packaging Products

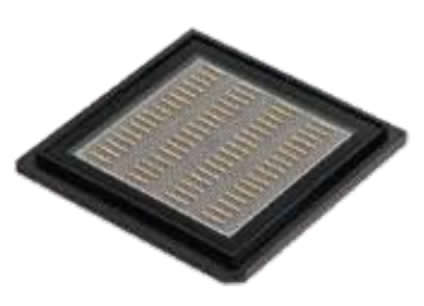

In addition to traditional edge-emitting laser devices, we also offer TOF, SL, and LI series vertical-cavity surface-emitting laser (VCSEL) chips. Covering wavelengths from 808nm to 940nm, these chips feature a maximum number of emitters per chip of 1216, output power ranging from 3.1W to 60W, and a divergence angle controlled between 20° and 22°. Combining high integration and narrow beam characteristics, they are suitable for emerging fields such as 3D sensing and laser ranging.

In terms of packaging, we provide various solutions including COS/COC/MCC: COS-packaged devices focus on high stability for precision instruments; MCC (micro-channel cooling) packaging achieves efficient heat dissipation via multi-layer copper foil heat sinks, supporting quasi-continuous wave (QCW) output with a peak power exceeding 11kW and a duty cycle of up to 20%, making it the ideal choice for high-power industrial processing.

3. Integrated Components: Laser Stacks and Pump Modules

To meet high-power application requirements, we have developed MCP and QCP series laser stack assemblies, enabling vertical or horizontal integration of multiple bars with a maximum of 60 bars per stack and output power ranging from hundreds of watts to tens of thousands of watts. Take the STD series pump module as an example: its HS12 model adopts macro-channel cooling technology, delivering a peak power of up to 16500W and supporting a QCW mode of 1ms@10Hz, with an electro-optical conversion efficiency exceeding 58%. It also offers an optional fast-axis collimation (FAC) configuration to effectively compress the beam divergence angle, making it suitable for large-scale industrial scenarios such as solid-state laser pumping and power battery busbar welding.

II. Core Technical Advantages: Dual Assurance of Performance and Reliability

The core competitiveness of our laser devices stems from precise control over key processes and technological innovation:

High-precision optical parameter control: Through advanced cavity passivation and wavelength calibration processes, product wavelength tolerance can be controlled within ±3nm, and spectral width (FWHM) can be as low as 2nm, ensuring beam monochromaticity and consistency. TE polarization ratio generally exceeds 97%, meeting the requirements of polarization-sensitive applications.

Efficient heat dissipation and packaging design:The five-layer copper foil heat sink of MCC packaging offers far superior heat dissipation efficiency compared to traditional macro-channel solutions, supporting high-load operation with a 20% duty cycle. The application of AuSn hard soldering technology significantly reduces packaging thermal resistance, extending device lifespan to over 20,000 hours and enabling operation in a wide temperature storage range of -40℃ to 85℃.

Customized adaptation capability: For special scenarios such as medical implant machining and semiconductor packaging, we can provide emitter pitch adjustment, customized pulse parameters (pulse width 200μs-500μs, frequency 160Hz-400Hz), and beam shaping services to achieve deep "device-scenario" matching.

III. Typical Application Scenarios: Cross-Domain Light Source Empowerment

Our diode laser products have been successfully deployed across multiple fields, forming differentiated solutions:

Industrial manufacturing: The 700W-class 940nm bar with MCC packaging can be used for automotive body laser welding and 3C component precision etching; multi-bar stack assemblies serve as high-power pump sources for fiber lasers, facilitating metal cutting and additive manufacturing.

Medical and healthcare: The 808nm band QCW stack device, with a customizable pulse width of up to 400ms and uniform energy density, is suitable for medical aesthetic equipment such as hair removal and spot removal; low-power VCSEL chips can be integrated into medical sensing instruments for non-invasive monitoring of human physiological signals.

Scientific research and national defense: Narrow-linewidth single-emitter chips provide stable light sources for laser spectroscopy experiments; high-reliability stack assemblies can serve as the core of the transmitting end for laser radar (LiDAR), meeting the stringent requirements of long-distance detection.

IV. Customized Services: Full-Link Support from Demand to Solution

For requirements involving special wavelengths, non-standard power, or custom-shaped packaging, we offer end-to-end customized services: from wafer specification confirmation and chip structure design to packaging process optimization and finished product testing, a dedicated technical team follows up throughout. Meanwhile, all products are accompanied by complete test certificates and ESD-safe cleanroom packaging to ensure delivery quality and transportation safety.

From basic chips to integrated stacks, our diode laser products have built a product ecosystem characterized by "performance grading, scenario adaptation, and flexible customization". With the advancement of industrial intelligence and medical precision, our products will continue to act as a key link connecting laser optics and computing systems in high-end manufacturing and cutting-edge scientific research, providing core power for the next generation of intelligent laser equipment.

For more information on our Diode Chip/Bar/Stack, please click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்