WhatsApp: +65 91904616 E-mail: sales@sintec.sg

WhatsApp: +65 91904616 E-mail: sales@sintec.sg

We are one of leading suppliers of high-power silica fiber cables for industrial medical and scientific applications. We offer fiber cables in a variety of fiber diameters protective tubings and connectors.

We offer high-performance, high-quality specialty optical fiber cables covering broad band spectral range, from UV (220nm) to Mid Infrared (18µm), for applications that include industrial manufacturing, military, environmental sensing, and space applications. In addition to the range of standard products, our fiber optic cables can be customized to meet the needs of the research & development environment, where the novel coupling and mixed bundles are often required.

UV/VIS/NIR (220 – 2500nm): Silica fiber cables, with a range of diameters and NAs are available with a variety of polymer and metal coatings. Innovative high power connectors can be selected for laser power delivery from diode laser modules and high power industrial lasers.

CIR (1.5 – 6.0µm): In the mid infrared, our chalcogenide infrared (CIR) fiber cables have optical transmission to match the output from LEDs and solid state infrared lasers including Quantum Cascade types.

PIR (4.0 – 18.0µm): In the mid infrared, our silver halide polycrystalline infrared (PIR) fiber cables are suitable for coupling to black body sources, LEDs, CO2 lasers and solid state infrared lasers including quantum cascade types.

Our optic laser cables are the best for laser power delivery with high brightness and beam quality. Robust design of our laser cables secures long term use for industrial and medical applications.

Our specialty is to provide high temperature assemblies (up to 600°C) for high power and/or vacuum applications by using metal-coated silica fibers. Bundles of metal-coated fibers are able to combine power from many laser modules to reach output in multi kW power range.

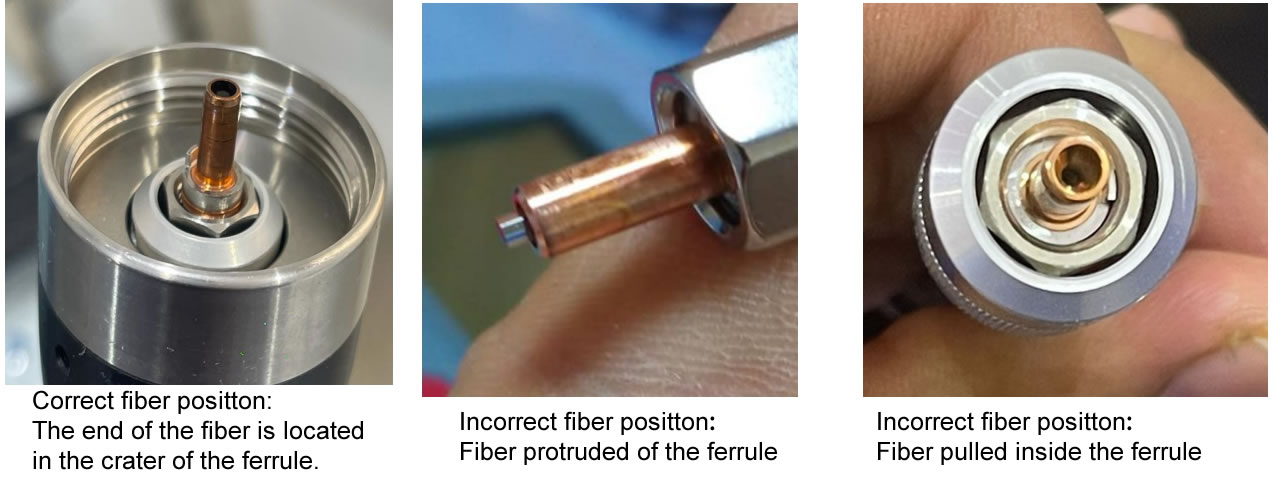

Our manufacturing technologies assure precise fiber position inside the connector ferrule and a perfect surface quality of the fiber end. Our quality control procedures and special equipment such as digital fiber microscope, infrared vision camera, power meter, beam profiler and 100W diode laser are used to test each cable before shipment to the customer.

| Spectral ranges | 0.18–1.2μm (UV-VIS) or 0.35–2.4μm (VIS-NIR) |

| Pure silica fiber core diameter | 100, 200, 300, 400, 600, 800, 1000, 1200, 1500µm |

| Numerical aperture | 0.22 ± 0.02 (Full acceptance angle 25°) 0.12 ± 0.02 (Full acceptance angle 14°) |

| Protective fiber jacket | Nylon, Tefzel, Acrylate, Al, Cu |

| Cable protective tube | PVC coated stainless steel monocoil, bend protected silicon coated stainless steel bend protection |

| Connector type | HP-SMA (High Power SMA); D-80 |

| Temperature range | -40°C to +600°C (Cu coated) |

| Cable length | 1.5 & 3m ( optional: from 5cm to 50m) |

| MCS-fibers in bundle | 3, 7, 19, 37, 64 |

*customized dimensions available on request

| Laser Cable Type | SMA | P-SMA | P+SMA | HP-SMA | HP-D80 |

| Max Laser Beam Power, W | 5 | 30 | 150 | 300 | 900 |

| Connector Type* | SMA 905 | SMA 905 free fiber end | SMA 905 free fiber end | SMA, free fiber end, epoxy free, long coupling nut | D80 free fiber end, epoxy free, metal radiator |

| Ferrule Material | ARCAP | ARCAP | ARCAP; Copper-Alloy | ARCAP; Copper-Alloy | Copper-Alloy |

| Fiber Centricity, μm | <6 | <6 | <6 | <10 | <10 |

| Protective Tubing* | Simplex | Polymer coated metal protection tube (optional PEEK) | |||

| Protective Tubing OD*, mm | 3.0 or 3.2 | 5.3; 6.4 | 5.3; 6.4 | 6.4 | 8.9 |

| Fiber Core Material | Pure fused silica: High OH¯ ( λ= 0.25 – 1.2 μm); Low OH¯ ( λ= 0.4 – 2.3 μm) | ||||

| Core Diameter*, μm | 200, 400, 600, 800 (optional: other diameter and core shape) | ||||

| Fiber Cladding Material | Fluorine doped fused silica | ||||

| Numerical Aperture* | 0.22 ± 0.02 (Full Acceptance Angle 25°), (optional: NA= 0.12 ± 0.02) | ||||

| Fiber Cable Length*, m | 1.5, 3.0, 5.0 (optional: from 5cm to 200m) | ||||

* Others available on request.

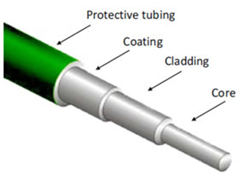

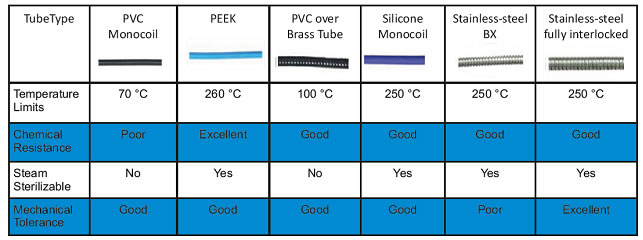

For assembling Optical Cables the multimode fibers with core from pure fused silica and the cladding from fluoride doped silica are used. A buffer material is then applied. A buffer coats the core and cladding, strengthens the fiber. In most assemblies polyimide is used as the buffer; other assemblies use aluminum or acrylate. Then protective tubing is applied over the core, cladding and buffer to protect the fiber and provide strain relief. The standard jacketing is stainless steel silicone monocoil. Precision optical Connectors terminate the cable and are precisely aligned to ensure concentricity of the fiber. Finally, end caps protect the fiber tips against scratches and contaminants.

The most critical issue in building laser power delivery system is choosing the right optical fiber cable. Three main parameters are important to make right selection:

One important consideration in ordering an optical fiber assembly is which fiber type you should specify for your application. Typically, the wavelength range needed for your application should match the wavelength range of the fiber type.

Low OH¯ and High OH¯ Optical Fiber: The optical attenuation characteristics are quite different for high OH¯ and low OH¯ optical fiber core material. For UV-VIS spectral range (λ = 0,18 - 1,2 μm) silica-silica fibers with High OH¯ content should be used and for VIS-NIR range (λ =0,35 -2,5 μm) – silica-silica fibers with Low OH¯ group concentration are more convenient.

The next significant parameter is the fiber core diameter. Smaller fiber cores are preferred in order to get the best beam quality and high flexibility. However optical fiber cables have several restrictions in their power transmitting capabilities, and there are important limitations to selecting the appropriate (smallest) fiber size. The laser itself imposes constraints on the smallest fiber that can be used.

| Maximum CW Power for Each Fiber Diameter | Fiber Specifications | |||

| Core dia. (um) | Square (mm2) | CW power (W) | Core | Pure silica |

| 50 | 0.0020 | 10 | Cladding | Fluorine doped fused silica |

| 100 | 0.0079 | 25 | Coating | Acrylate coating (-40 to 85oC) |

| 200 | 0.0314 | 50 | Silicone resin coating (-40 to 180oC) | |

| 400 | 0.1256 | 100 | Polyimide coating (-190 to 385oC) | |

| 600 | 0.2826 | 300 | ||

| 800 | 0.5024 | 600 | ||

| 1000 | 0.7850 | 800 | ||

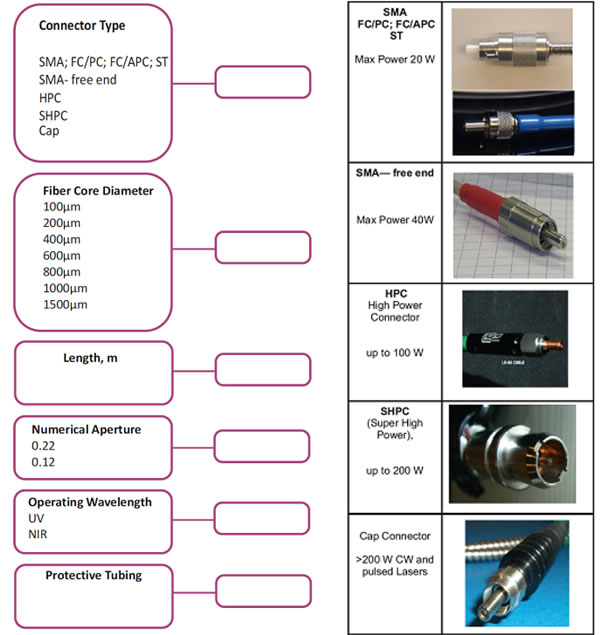

Selecting the right connector for your needs can be complicated by the many choices available today. Choosing the best fiber optic connector for any installation will have an impact on how efficient and cost-effective the job is completed.

In today’s laser power fiber delivery system, there are various optical fiber connector types: SMA, ST, FC/PC, FC/APC, DL80, D-200 connectors, cap-customized. Bespoken Mitsubishi connector design may include ferrule protection by sapphire ring to prevent metal evaporation by intensive laser beam.

High power connectors feature an air-gap design, where the fiber extends into free space between 1.1mm to 1.5mm, providing an epoxy-free region where thermal energy can be safely dissipated without burning the surrounding material. This is the key mechanism for failure in standard connectors.

In addition we utilize a number of unique methods of polishing fiber tip or fusing a glass end cap to the end of the fiber (cap connector) to maximize power handling.

High power connectors compatible with SMA 905 and FC receptacles are offered.

Finally, each cable assembly goes through the tight quality control with several examinations during the fabrication process, including extensive inspection of fiber tip quality by fiber check technique. Data will help alleviate the confusion by reviewing the basic considerations prior to deciding on the best connector for an installation.

We offer excellent fiber cables for a mid-Infrared spectral range 1.1 – 6.5 μm. Based on Chalcogenide Infra-Red (CIR-) fibers, the fiber cables are used in a wide range of applications including power delivery of QCL, spectroscopy, flexible IR-imaging systems, etc. CIR- fiber cables are available with a variety of standard fiber diameters, SMA-905, FC/PC, FC/APC connectors, and several types of protective tubing. Our manufacturing technologies assure precise fiber position inside the connector ferrule and a perfect surface quality of the fiber end. Before shipping, each fiber cable passes through detailed Quality Control procedure.

| Optical fiber type | Chalcogenide step index multimode |

| Wavelengths range | 1.1 – 6.5 µm |

| Fiber core/cladding sizes (μm) | see parameters of standard chalcogenide fibers |

| Effective numerical aperture (NA) | see parameters of standard chalcogenide fibers |

| Minimum bending radius depending on protective sheathing | PEEK tubing – 130mm metal PVC coated tubing – 80mm stainless steel tubing – 80mm stainless steel silicone-coated tubing – 130mm |

| Connectors | SMA-905; FC/PC or FC/APC |

| Temperature range | -50°C to + 90°C |

| Part number | Type | Core, µm | Cladding, µm | Protective jacket, µm | NA | Min bending radius, mm |

| STA-CIR8/300 | Step index single mode | 8±1 | 300±15 | 400±20 | 0.25±0.02 | 60 |

| STA-CIR50/250 | Step index few mode | 50±3 | 250±10 | 410±20 | 0.13±0.02 | 50 |

| STA-CIR250/300 | Step index multimode | 250±10 | 300±15 | 400±30 | 0.30±0.03 | 60 |

| STA-CIR340/400 | Step index multimode | 340±10 | 400±15 | 510±30 | 0.30±0.03 | 80 |

| STA-CIR500/550 | Step index multimode | 500±10 | 550±15 | 700±30 | 0.30±0.03 | 100 |

We offer excellent fiber cables for a broad Mid-Infrared spectral range 3–17μm. Based on Polycrystalline Infra-Red (PIR-) fibers, our fiber cables are used in a wide range of applications including Mid-IR light delivery, spectroscopy, remote temperature sensing, etc. PIR-fiber cables are available with a variety of standard fiber diameters, with different connectors (SMA-905, FC/PC, and FC/APC), and several types of protective sheathing. Our manufacturing technologies assure precise fiber position inside the connector ferrule and a perfect surface quality of the fiber end. Before shipping, each fiber cable passes through the detailed quality control procedure.

| Optical fiber type | Polycrystalline step index multimode |

| Wavelengths range | 3 - 17 m |

| Fiber core/cladding sizes (m) | see standard fiber parameters on the second page |

| Effective Numerical Aperture (NA) | 0.30 +/- 0.05 |

| Minimum bending radius depending on protective sheathing | PEEK tubing – 130mm metal PVC coated tubing – 80mm stainless steel tubing – 80mm stainless steel silicone coated tubing – 130mm |

| Connectors | SMA-905, FC-PC or FC-APC with titanium ferrule |

| Temperature range | -50°C to + 80°C |

| Part number | Type | Core, μm | Cladding, μm | Protective jacket, μm | NA | Min bending radius, mm |

| STA-PIR240/300 | Step index few modes | 240±10 | 300+0/-10 | no | 0.35±0.05 | 45 |

| STA-PIR400/500 | Step index multimode | 400±10 | 500+0/-15 | no | 0.35±0.05 | 75 |

| STA-PIR600/700 | Step index multimode | 600±15 | 700+0/-15 | no | 0.35±0.05 | 100 |

| STA-PIR900/1000 | Step index multimode | 860±20 | 1000+0/-20 | no | 0.35±0.05 | 150 |

Our Power Fiber Cables (PFC) with PC-SMA905 connector exploit the air-gap-ferrule design, where the fiber prolongs into free space securing an epoxy-free area, where thermal energy can be safely dissipated without burning the surrounding material, making them ideal for high-power applications.

A heat-sink is attached to the rear of the connector, which conducts extraneous heat away from the fiber, further reducing the possibility of breakdown.

Each cable assembly goes through the tight Quality Control with several examinations during the fabrication process, including extensive inspection of fiber tip quality by FiberCheck® technique, leading , as a result, to a special product.

STHPFC-9 General Specifications

| Core Core diameter (μm) | Pure fused silica (low OH-) 9 |

| Cladding Cladding diameter (μm) | Fluorine doped fused silica 135 |

| Coating | Polyimide coating (-190°C to 385: C) |

| Protective tube | Silicon coated Stainless Steel |

| Numerical aperture | 0.22 |

| Fibre connector Length | PC-SMA905 3 m |

| Max. laser power (W) | 1 W |

| Short term bending radius (cm) Long term bending radius (cm) | 3.6 14.4 |

High-power Fibers for Diode Lasers

High Power (HP-) Silica Cables are assembled with innovative HP-SMA-connectors made with inner Copper ferrules for free fiber end position and capable for durable delivery of laser power of high intensity in pulsed or cw mode in the range below 1kW (cw).

Super High Power (SHP-) Silica Cables could deliver up to several kW from Diode and Solid State lasers resulting from their assembly with a larger size SHP-connectors of special design with diameter spans 2.5, 4, 10 and 15mm - or with Mitsubishi connectors of D-80 and D-200 types. Bespoken SHP-connector design may include Copper ferrule protection by Sapphire rings to prevent Copper evaporation by intensive laser beam.

| Fiber Core Diameter (μm) | 100 | 200 | 400 | 600 | 800-1000 | 1000-2000 |

| Max Power (kW) | >0.1 | >0.6 | >1 | 2-4 | 6-8 | >8 |

HP- and SHP-cables can be protected by polymer coated metal armor or MKS-jacketing (Stainless Steel / Kevlar / Silicon) for durable protection of silica fibers inside – which diameter spans from 100μm to 2mm. In-house technology of precise assembly allows to assembled single HP & SHP-cables with a length from 50mm to 100m.

All silica fiber NA = 0,22, default length 1m, protected in stainless steel (inside) and fabric silicone (outside) tubing (out diameter 6mm, grey), terminated with 2x SMA905 free end connectors, electrically disconnected

| Part number | STA-SMA905-F100 | STA-SMA905-200 | STA-SMA905-400 | STA-SMA905-600 |

| Fibre core diameter (μm) | 100 | 200 | 400 | 600 |

| Fibre cladding diameter (μm) | 140 | 280 | 480 | 720 |

| Max. laser power (W) | 70 | 150 | 150 | 150 |

| Short term bending radius (cm) | 1.1 | 2.1 | 3.6 | 5.4 |

| Long term bending radius (cm) | 4.2 | 8.4 | 14.4 | 21.6 |

Order Information:

STA-SMA905-Fxxx-yyyy: xxx is core diameter in um and yyyy is fiber length in mm.

1) HP- & SHP-cables based on UV- & NIR-Silica glass for flexible power delivery of Diode, Solid State, DPSS and Gas lasers – which durable exploitation is secured by low optical losses in fiber of special structure, by innovative design of HP- & SHP-connectors, by proper fiber protection with armored MKS-jackets and by inhouse test of all cables performance;

2) HP- & SHP-cables based on special Silica fiber coated by Aluminium, Copper or Copper alloys – where unique technology of metal freezing on lateral fiber surface doubles fiber bending strength, accelerates dissipation of laser induced heat from the fiber under delivery of high power and enables cables applications at high temperatures up to 600°C;

3) HP-Silica Fiber Summarizers for fiber collection of power from 3 to 7 Diode Laser Modules - provides above 100W of combined laser power at the input of HP-Refocusator of special design and then this refocused power is homogenized by HP-fiber Homogenizer. This 3 component HP-Silica Fiber System provides flexible solution for multiwavelength laser combination and for medical applications like hair epilation in cosmetology;

4) HP-Silica Fiber Dental Applicators (SFDA) – for disposable applications in advanced laser dentistry and ENT laser surgery. Variety of HP-Silica cables for medical lasers includes the design where fibers are assembled with electric wires in the same protective jacket – as it is required for remote control and variation of laser parameters during laser surgery. Distal fiber ends may be terminated with a variety of hand-pieces of bespoke design.

Used to deliver laser beam with high coupling efficiency and high damage shreshold.

Ordering Information:

STH-xxxxx-Fyyy-z, where xxxx means connector (such as SMA905…), yyy means core diameter in um, z means fiber length in meter. For example, STH-SMA905-F400-2 is an optical fiber with SMA905 connectors, core 0.4mm and 2m long.

Features

Applications

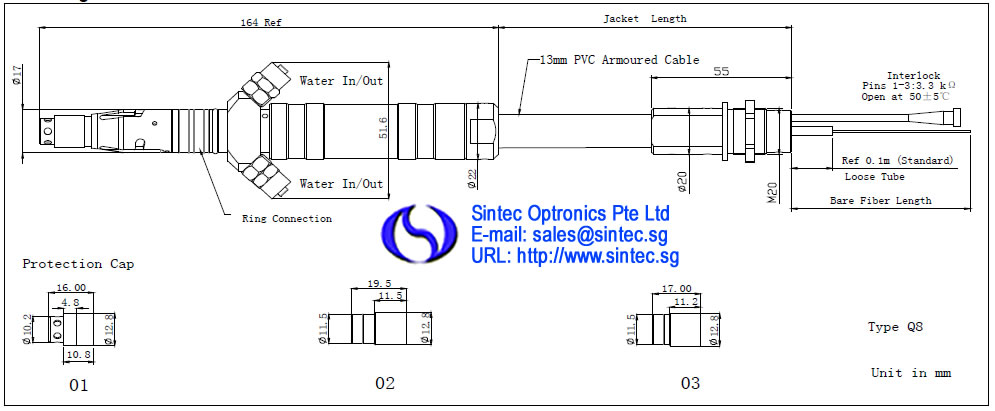

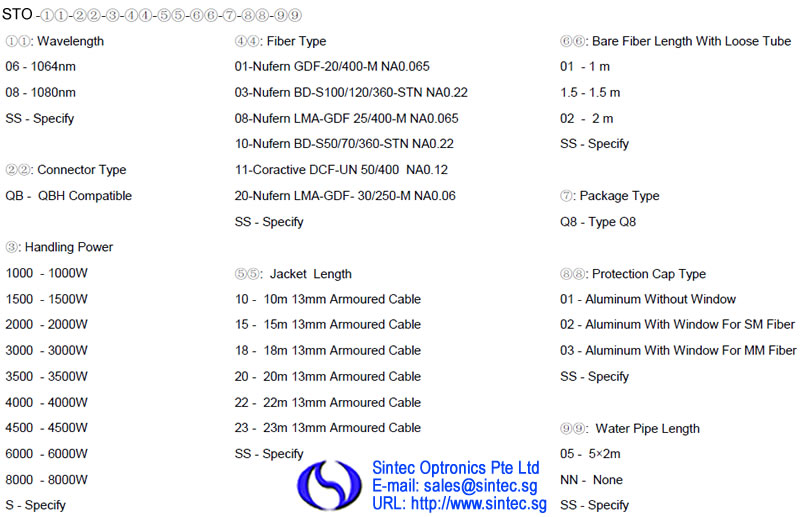

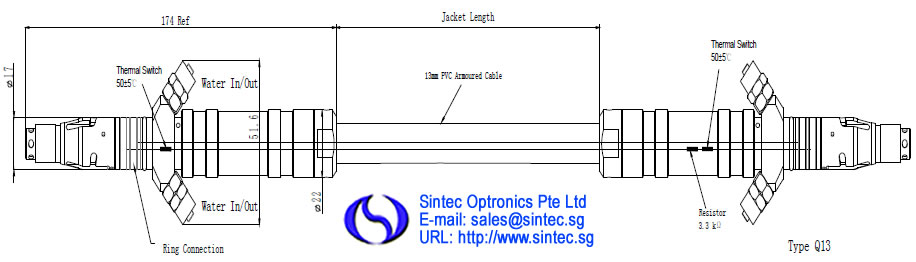

| Unit | Parameter | |

| Operating Wavelength | nm | 900~1000(Nominal Center Wavelength 950nm) 1030~1090(Nominal Center Wavelength 1064 nm) |

| Typ. Transmission Ratio | - | 99% |

| Min. Transmission Ratio | - | 98% |

| Max. Handling Power (CW) | W | 1000, 2000, 4000, 6000 ,8000 or Specify |

| Pulse Power | - | Max. 10KW @10ms Max. 50KW @1ms Max. 1MW @50ns |

| Loss Power Handling Capability | - | 1KW for 10 min 500W Continuously |

| Nominal Beam Pointing Accuracy | deg | 1 |

| Min. Beam Ellipticity | - | 0.92 |

| Max. Fiber Tensile Load | N | 5 |

| Package Material | - | Stainless Steel / Aluminum / Copper |

| Operating Temperature | ℃ | +10 to +50 |

| Storage Temperature | ℃ | -10 to +75 |

| Max. Water Pressure | Bar | 4 |

| Flow of Water | L/min | 1.5-2.5 |

| Fiber Length ≤15 m | - | The Fiber Length Tolerance is -10cm |

| 15m<Fiber Length ≤30m | - | The Fiber Length Tolerance is -20cm |

| Jacket Length≤15m | - | The Jacket Length Tolerance is +0.2/-0.1m |

| 15m<Jacket Length ≤30m | - | The Jacket Length Tolerance is +0.4/-0.2m |

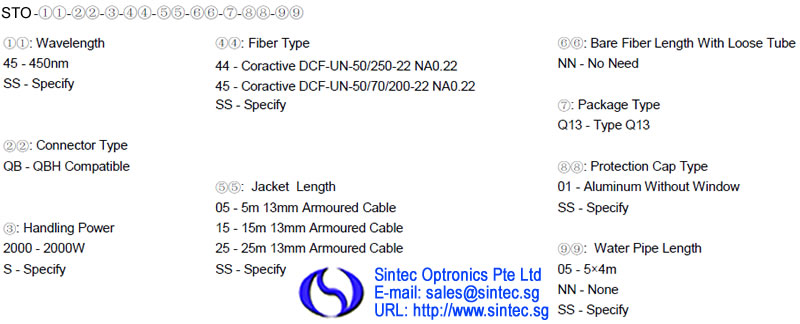

| Unit | Parameter | |

| Operating Wavelength | nm | 440~460(Nominal Center Wavelength 450nm)or others |

| Typ. Transmission Ratio(By Design) | - | 98% |

| Min. Transmission Ratio(By Design) | - | 96% |

| Max. Handling Power (CW) | W | 2000 or Specify |

| Pulse Power | - | Max. 10KW @10ms Max. 50KW @1ms Max. 1MW @50ns |

| Loss Power Handling Capability | - | 1KW for 10 min 500W Continuously |

| Nominal Beam Pointing Accuracy | deg | ≤1 |

| Min. Beam Ellipticity | - | 0.92 |

| Max. Fiber Tensile Load | N | 5 |

| Fiber Cable Lengths Tolerance | M | ±0.5 |

| Package Material | - | Stainless Steel / Aluminum / Copper |

| Operating Temperature | ℃ | +10 to +50 |

| Storage Temperature | ℃ | -10 to +75 |

| Max. Water Pressure | Bar | 8 |

| Flow of Water | L/min | 1.5-3 |

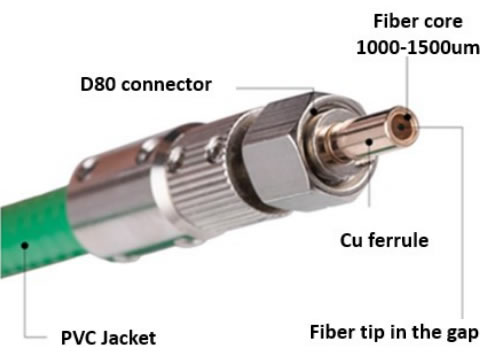

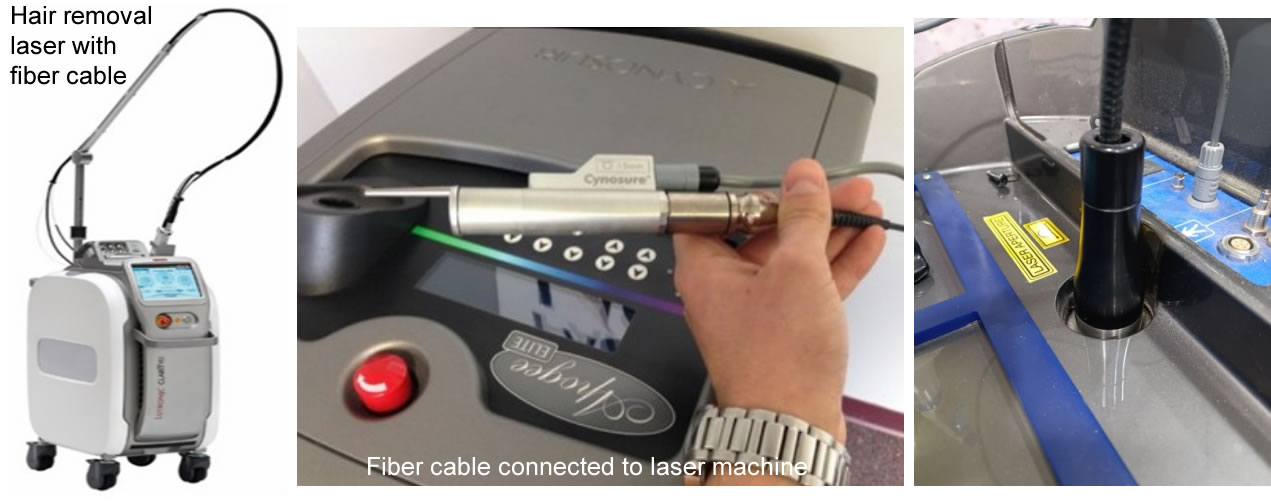

Recently, laser hair removal, a cosmetic procedure that uses lasers with radiation in the near infrared range (700 - 1063nm), has gained great popularity. The radiation of this range of light is well absorbed by melanin, which results in hair follicle destruction without subsequent restoration.

Today, there are many different types of hair removal lasers in the market. Despite their differences they all share one common feature, fiber optic cable. All hair removal lasers use fiber optic cable to transport the powerful laser beam to the target.

Fiber cables for hair removal, require large core diameter fibers to guide the light from the laser source to the tissue, from 1000 μm to 2000 μm, and high-quality fiber tip polishing is critical for the application. Failure can result in fiber burnt and malfunction of the laser application.

Fiber Cables for Hair Removal (specification)

| Cable type | STA-NIR1000-D80 | STA-NIR1200-D80 | STA-NIR1500-D80 |

| Fiber specifications | Core: 1000um ± 2% primary coating: 1100um ± 2% secondary coating: 1180um ± 3% protective coating: 1400um ± 5% |

core: 1200um ± 2% primary coating: 1320um ± 2% secondary coating: 1400um ± 3% protective coating: 1600um ± 5% |

core: 1500um ± 2% primary coating: 1650um ± 2% secondary coating: 1840um ± 3% protective coating: 2000um ± 5% |

| Numerical aperture (NA) | 0.22±0.02 | 0.22±0.02 | 0.22±0.02 |

| Spectral range | 0.4 – 2.4um | 0.4 – 2.4um | 0.4 – 2.4um |

| Connectors | D80 | D80 | D80 |

| Ferrule material | Cu | Cu | Cu |

| Fiber centratton in the ferrule | <10um | <10um | <10um |

| Cable length | Up to 5m | Up to 5m | Up to 5m |

| Protective tubing | PVC metal coated | PVC metal coated | PVC metal coated |

There are two very critical elements in the design of a fiber cable for hair removal laser, centricity of the fiber at the connector ends and fixation of the fiber at the connectors. Uncentered fiber may result in fiber tip damage, burnt, and can also harm the operator or patience. Inadequate fixation of the fiber at the connectors can lead to fiber protrusion or pull inside the connector. As a result, the laser focusing disrupts and the cable fails to perform.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616