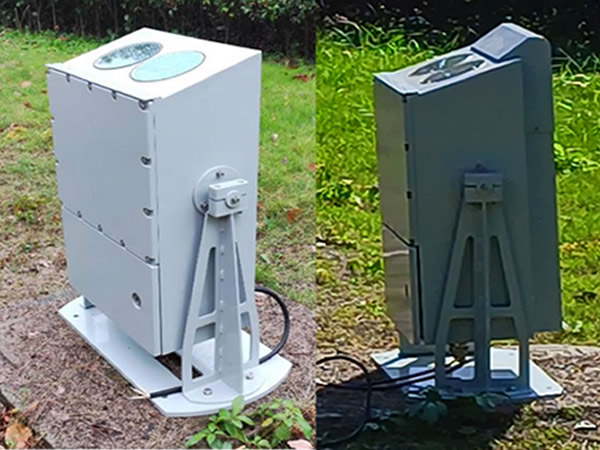

High Precision Laser Cutting Machine- PDC Drill Bits

The PDC (polycrystalline diamond compact) drill bit uses 35CrMnSi ultra-high strength alloy steel, forged into cylindrical blanks. The traditional process involves CNC turning and five-axis milling of spiral grooves to enhance the drill bit's anti-chipping property, optimize chip removal efficiency, and reduce drilling resistance. Now, with our PDC drill bit laser cutting machine, these complex structures can be processed in one go, significantly improving efficiency and quality. It can simultaneously cut spiral grooves and internal cooling channels with one-step forming, eliminating the need for subsequent treatments. After cutting, it can directly proceed to next processes such as drill welding, heat treatment, and surface strengthening. The cutting speed is fast, reducing the single-piece processing time from hours to minutes. It features high groove accuracy, small slit width, narrow heat-affected zone, eliminates clamping deformation risks, ensures geometric consistency of spiral grooves, and avoids surface micro-cracks caused by traditional grinding, extending the drill bit's service life. One device can complete the cutting and blanking of complex grooves for coring bits in various specifications and styles, such as peach-shaped, gear-shaped, and flat-topped inserts, greatly reducing costs and processing cycles. It is a must-have core path for upgrading high-end drilling tools!

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்