Our laser speckle reducers are nothing other than moving diffusers. But the way they are actuated is absolutely unique. Two innovative tehttp://www.sintec.sg/sintec/images/button_ok.gifchnologies are offered, each with its own advantages.

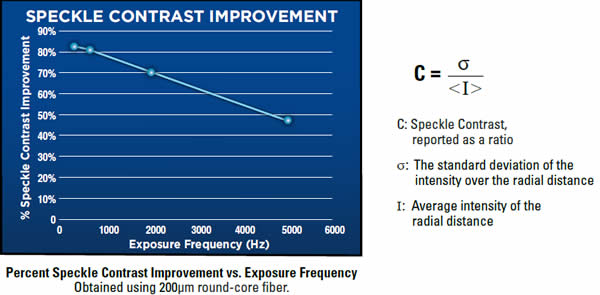

Our proprietary De-Speckler technology averages the modal noise within an optical fiber. This reduction in speckle is an ideal choice for fiber assemblies used in the Life Sciences, Digital Laser Projection, Interferometry, Laser Beam Homogenization, Lithography, and Metrology. For many fiber coupled applications, modal noise interferes with optimal performance. We have developed a small, simple and integrated de-speckling system which maximizes performance and reliability in illumination, with no optical loss.

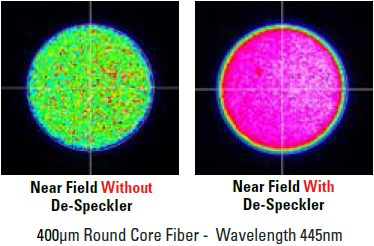

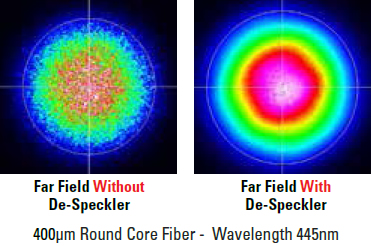

Speckle is a random granular pattern commonly observed in the output beam of a laser. It is characterized by many dark and light spots of different intensities visible in a given cross section of the laser beam. This effect occurs as a result of interference between various propagation modes of the light.

The reduction of speckle is important for applications where a homogeneous laser output of uniform intensity is ideal, such as laser-scanning microscopy, flow cytometry, and DNA sequencing. By using the De-Speckler to average the modal noise and greatly reduce speckle, maximized performance can be achieved. Other benefits resulting from speckle reduction can include faster integration times, improved signal-to-noise ratios, and higher throughput.

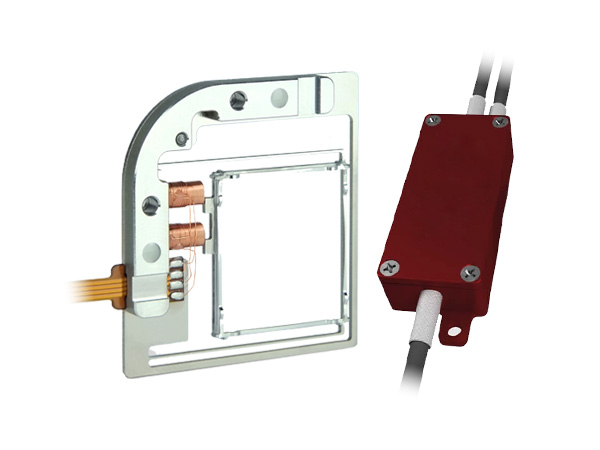

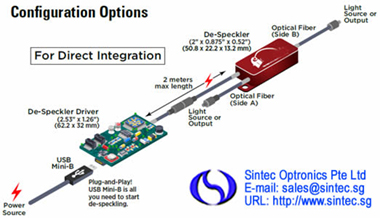

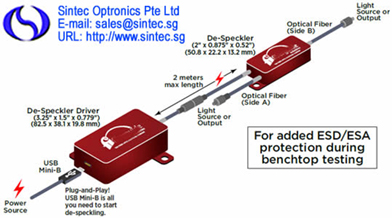

Our speckle reduction solution has a small form factor and is in-line with a customizable fiber assembly. The fiber size, core shape, jacketing, connectors, and length can all be customized to perfectly suit your application. Please view the product specifications for more information.

This product is popularly paired with our square core fiber and RARe Motheye anti-reflection technology.

Life sciences: bioanalytical instrumentation, flow cytometry, gene sequencing, microscopy, spectroscopy

Digital laser projection

Interferometry

Laser beam homogenizers

Lithography

Metrology

Power supply: +5 Volts

Power consumption: < 1 Watt

Wavelength range: 400nm – 1550nm

Fiber core size: 100μm – 400μm

De-speckling rate: up to 5000 Hz

Fiber types: all Silica optical fiber; plastic clad fiber; round or square core fiber; RARe Motheye available.

Jacket types: acrylate, nylon, polyimide, Tefzel

Assembly types: single fiber assemblies

Connector types: 905 SMA; 906 SMA; FC/PC; FC/UPC; FC/APC; ST/PC; ST/UPC; ST/APC; cleaved ends; polished ends; round 2.5mm ferrule; custom connectors

A way to reduce speckle noise from a laser-based system is by dynamically diffusing the laser beam. Our STOT-LSR-4C speckle reducer averages multiple speckle patterns by dynamically displacing a diffuser, and by doing so creates a more homogeneous, speckle-free beam. The STOT-LSR-4C has an aperture of 18.5x18.5 mm and is especially suitable for laser-based cinema projectors where high laser powers and large beam diameters are used. The diffusor is mounted in a metallic frame and is set into motion by the reluctance force generated in the oscillating magnetic field of a driving coil.

If required, STOT-LSR-4C can combine two oscillating diffusors rotated by 90°, realizing optimized despeckling in both directions. The compact driving electronics, assembled on a flexible plastic substrate, stabilizes the resonance Frequency in closed-loop mode and includes an error signal.

Mechanical specifications

Clear aperture | 18.5 x 18.5 | mm |

External dimensions | 35.2 x 37.9 x 5.8 | mm |

Housing diameter | 30.0 | mm |

Height | 14.5 | mm |

Weight | Full device: 11.0 Diffuser: 0.29 | g |

Mechanical clamping | 2x M2 screws | |

Minimal weight of anchor mass | 500 | g |

Performance specifications

Oscillation amplitude (peak to peak) | Min: 0.6 Typical: 0.8 Max: 2.0 | mm |

Oscillation frequency | 120 ± 10 | Hz |

Device start-up time (typical) | 20 | s |

Optical specifications

Material | Fused silica | |

Diffusion angle (FWHM) | 8.5 (up to 20 on request) | ° |

Transmission wavelength | VIS coated: 440-660 Uncoated: approx. 200-2200 | nm |

Transmission | VIS coated: >98 Uncoated: >94 | % |

Depolarization | < 0.1 | % |

Coating | High power, double-sided | |

Damage threshold | > 600 | W/cm2 |

Scratch/dig | 60/40 | Over full clear aperture of diffuser |

Electrical specifications

Power supply (micro-USB or solder pads)¹ | 3.4-5 | VDC |

Power consumption (with std. electronics | 50 mW | mW |

Environmental specifications

Operating temperature at fixed startup temperature Ts² | Ts-5 to Ts+55 | °C |

Storage temperature | -40 to +85 | °C |

Start-up temperature | -30 to +85 | °C |

Mechanical shock | 500 | g |

Cycle life | >40 000 | hours |

Overview of available standard products

Standard Product | Coating | Diffusion angle |

STOT-LSR-4C-L-18x18-9-T2-VIS | VIS-coated | 8.5° |

STOT-LSR-4C-L-18x18-9-T2-NOC | uncoated | 8.5° |

Accessories | Description |

Bracket kit STOT-LSR-4 | Bracket for single and double diffusor configuration |

STOT-LSR-4C-LL-mounting kit | Mounting kit for double diffusor configuration |

PS-5V-US | 5V DC micro-USB power supply with US plug |

PS-5V-EU | 5V DC micro-USB power supply with EU plug |

Assemblies | Components to order |

STOT-LSR-4C-L (no bracket) | 1x STOT-LSR-4C, 1x Power supply |

STOT-LSR-4C-L (with bracket) | 1x STOT-LSR-4C, 1x Bracket-kit LSR-4, 1x Power supply |

STOT-LSR-4C-LL (double diffusor configuration with bracket) | 2x STOT-LSR-4C, 1x Bracket-kit LSR-4, 1x STOT-LSR-4C-LL-mounting kit, 2x Power supply |

Control

The STOT-LSR-4C is driven using a 5V DC power supply. No further driver electronics are needed; the device settles into its optimal trajectory once powered on.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616