Our CNC2000 control card and software can maximally support 6-axis control at the same time. It can be used in the numerical control system of 3-axis linear motion + 3-axis rotational motion (X,Y,Z,C,A,B) or 6-axis rotational motion (6-joint mechanica

Our CNC2000 control card and software can maximally support 6-axis control at the same time. It operates under Windows such as Win10, Win7, Win2000, WinXP, Windows98, WindowsSME or Windows95. It can be used in the numerical control system of 3-axis linear motion + 3-axis rotational motion (X,Y,Z,C,A,B) or 6-axis rotational motion (6-joint mechanical arm). Also it can control all the lasers in the market such as YAG lasers, CO2 lasers, fiber lasers and ultrafast lasers.

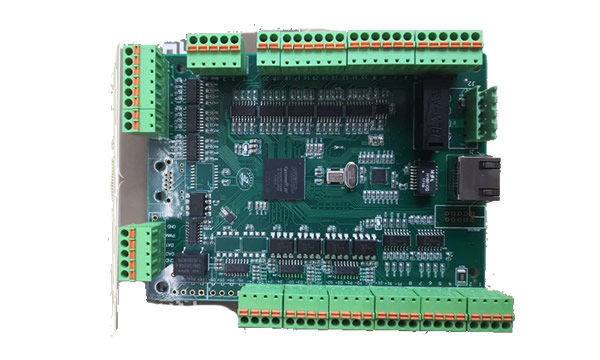

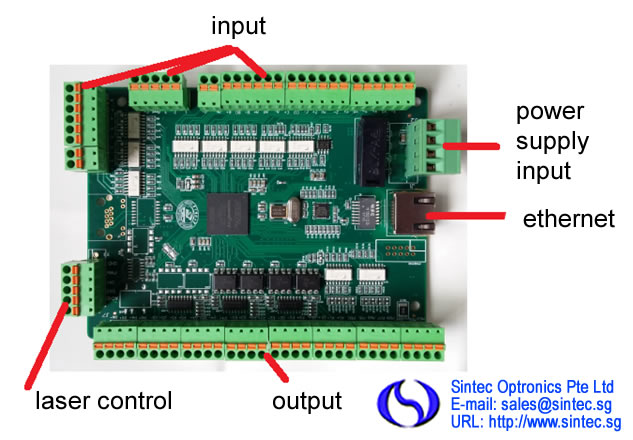

The CNC control card is an Ethernet card which is more convenient for connections. The advantages and features of the CNC control card are

Better stability, anti-interference and precision than traditional PCI card

More convenient for connections

No need to have a PCI slot to insert the control card

Operate in all versions of Windows systems

Operate in laptop or desktop computers

Can output 0-10V analogue voltage to achieve the real-time control of the fiber laser power

Can output 24V PWM signals to control the frequency and pulse width of the fiber lasers or CO2 lasers

One control card can support 6-axis system and combined 2 cards can support 10-12-axis system

The number of the input ports has been increased to 32 to achieve multi-station control and various kinds of logic control according to different input signals

Our control cards are made with multi-layer circuit boards and power source and ground are separated into two layers. Although the card costs more, they improve the performance of anti-interference. Thus our cards can be used in precise control.

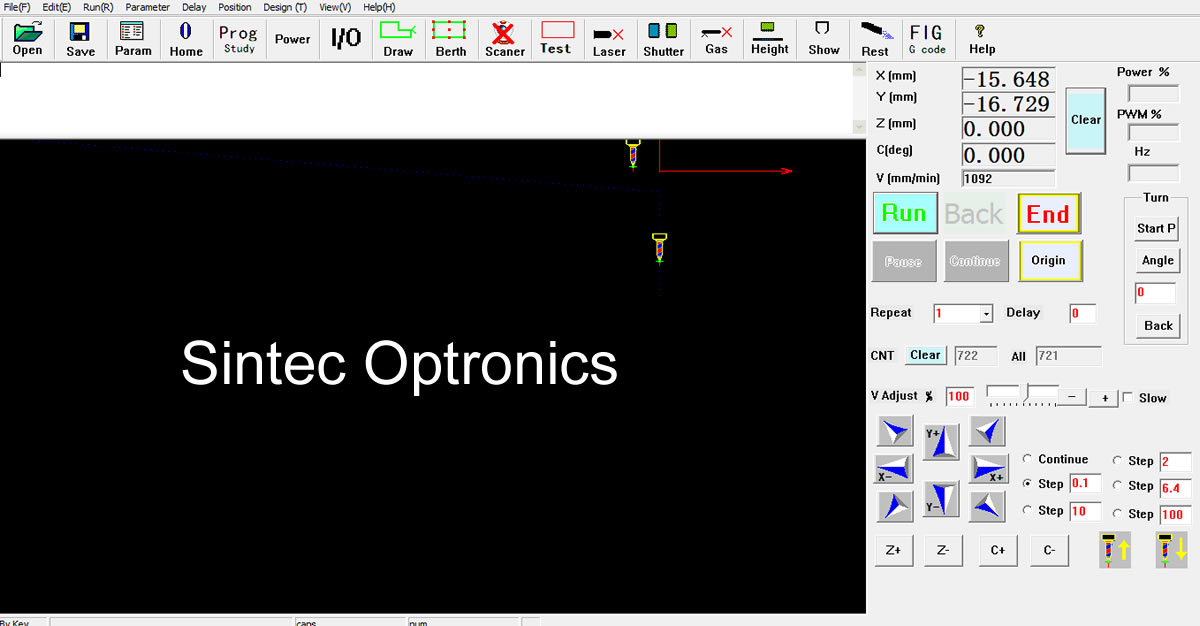

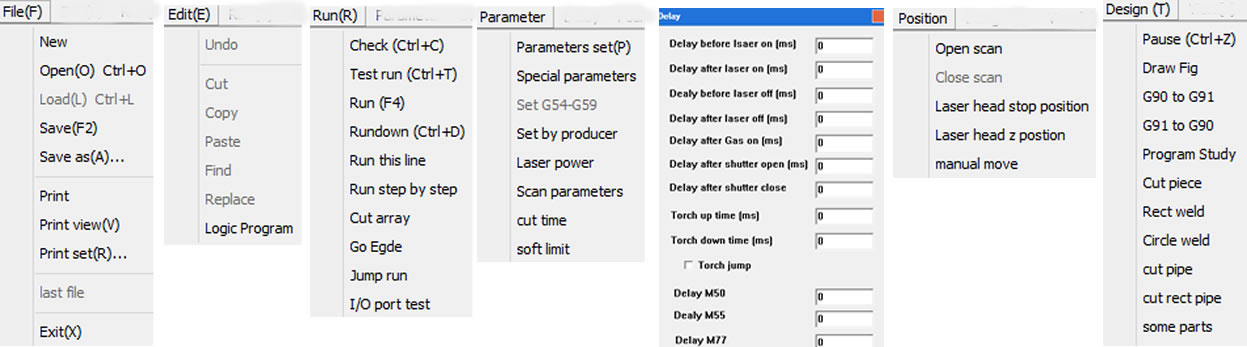

Our software’s functions are strong and easy to operate. The programming is simple and easy. There are 3 methods to write a programming: automatic conversion of PLT and DXF files, teaching or CNC programming. The software programming panel is as follows:

The main functions of the software programming are as follows:

The main programming points are as follows:

Maximum axis: 6

Program verification function

MDI function

Absolute/increment programming (G90, G91)

Programming using inch, metric, pulse number (G20, G21, G22)

Mirror function (G24, G25)

Zoom (magnification/demagnification) (G50, G51)

Automatic, step, manual, home function

Fast position (G00), linear interpolation (G01)

Arc interpolation (G02, G03)

Pause (G04), screw thread function (G33)

Set/back zero (G29, G30)

Reverse clearance compensation, beam diameter compensation (G40, G41, G42)

Coordinate rotation (G68, G69)

Sub-function

Static/dynamic emulation

Max stepping frequency: 200000Hz

Automatic acceleration/deceleration

Automatic conversion of PLT and DXF files

| Part number | Description |

| ST-CNC2000-4S | 4-axis control and to switch on/off laser beam such as YAG laser |

| ST-CNC2000-4M | 4-axis control and to fully control all types lasers such as YAG, CO2 or fiber lasers |

| ST-CNC2000-6S | 6-axis control and to switch on/off laser beam such as YAG laser |

| ST-CNC2000-6M | 6-axis control and to fully control all types lasers such as YAG, CO2 or fiber lasers |

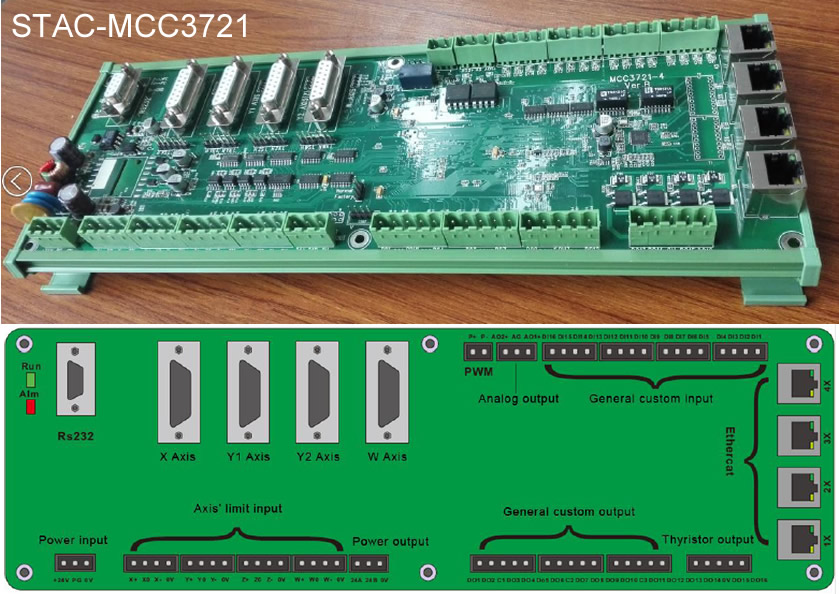

The control boards used to control lasers, laser cutting heads, XYZW motion and capacitor height sensor in the cutting heads. STAC-MCC3721H is to control XYZ 3-axis motion and STAC-MCC3721NC is to control XYZW 4-axis motion.

The I/O ports are defined as following table.

| Port | Function | Remark | |

| Power input | +24V | DC24V input + end | 24V/10A DC. Recommend to use DC 24V/10A power supply |

| PG | protective ground | ||

| 0V | DC input - end, power GND | ||

| Axis’ limit input | X+ | X Axis’ positive limit input, special signal, low-level propagation is effective. | X Axis’ limit input |

| X0 | X Axis’ origin signal, special signal, low-level propagation is effective. | ||

| X- | X Axis’ negative limit input, special signal, low-level propagation is effective. | ||

| 0V | GND, X Axis’ limit signal COM port | ||

| Y+ | Y Axis’ positive limit input, special signal , low-level propagation is effective. | Y Axis’ limit input | |

| Y0 | Y Axis’ origin signal, special signal, low-level propagation is effective. YY Axis’ negative limit input, special signal, low-level propagation is effective. 0V GND, Y Axis’ limit signal COM port | ||

| Y- | Y Axis’ origin signal, special signal, low-level propagation is effective. YY Axis’ negative limit input, special signal, low-level propagation is effective. 0V GND, Y Axis’ limit signal COM port | ||

| 0V | Y Axis’ origin signal, special signal, low-level propagation is effective. YY Axis’ negative limit input, special signal, low-level propagation is effective. 0V GND, Y Axis’ limit signal COM port | ||

| Z+ | Z Axis’ positive limit input, special signal, low-level propagation is effective. | Z Axis (standby ) input | |

| Z0 | Z Axis’ origin signal,special signal,low-level propagation is effective. | ||

| Z- | Z Axis’ negative limit input,special signal,low-level propagation is effective. | ||

| 0v | GND, Z Axis’ limit signal COM port | ||

| W+ | W Axis’ positive limit input,special signal,low-level propagation is effective. | W Axis(Rotation Axis / standby ) input | |

| W0 | W Axis’ origin signal,W | ||

| W- | W Axis’ negative limit input,special signal,low-level propagation is effective. | ||

| 0v | GND, W Axis’ limit signal COM port | ||

| Axis’ controlling ports | X | X Axis’ controlling signal | DB15female |

| Y1 | Y1 Axis’ controlling signal | ||

| Y2(Z) | Y2(Z)Axis’ controlling signal | If Y Axis is set up as dual - drive mode, it is Y2Axis; if Y Axis is set up as single drive mode, it is Z Axis’ controlling port( standby ). | |

| W | W Axis’ controlling signal | Rotation Axis( standby ) | |

| General custom outputs | DO1 | DO1 general output port | The function of output port can be set up arbitrarily by software. Passive output port has the same output TTL with COM port. |

| DO2 | DO2 general output port | ||

| COM1 | general output COM port | ||

| DO3 | DO3 general output port | ||

| DO4 | DO4 general output port | ||

| DO5 | DO5 general output port | ||

| DO6 | DO6 general output port | ||

| COM2 | general output COM port | ||

| DO7 | DO7 general output port | ||

| DO8 | DO8 general output port | ||

| DO9 | DO9 general output port | ||

| DO10 | DO10 general output port | ||

| COM3 | General output COM port | ||

| DO11 | DO11 general output port | ||

| DO12 | DO12 general output port | ||

| Thyristor output | DO13 | DO13 thyristor output port | DCV output: 24V, drive current: 1A |

| DO14 | DO14 thyristor output port | ||

| COM4 | Thyristor output COM port | ||

| DO15 | DO15 thyristor output port | ||

| DO16 | DO16 thyristor output port | ||

| Power output | 24A | The first DC24V output +end | Can be used as Axis’ limit switch/general output port can supply standard TTL |

| 24B | The 2nd DC24V output +end | ||

| 0V | The GND for DC24V output | ||

| PWM output | P+ | PWM signal output +end | The TTL of PWM output is 24V/5, which can be configured by the jumper nearby. |

| P- | PWM signal output -end | ||

| Analog output | AO1+ | Analog output port +end | The voltage of analog output is from 0V to 10V, which can be configured by software. |

| AG | The GND for analog output | ||

| AO2+ | Analog outpot port +end | ||

| AI | Analog input | ||

| General input | DI1 | general input port, low-level propagation is effective (Default) | |

| DI2 | general input port, low-level propagation is effective (Default) | ||

| DI3 | general input port, low-level propagation is effective (Default) | ||

| DI4 | general input port, low-level propagation is effective (Default) | ||

| DI5 | general input port, low-level propagation is effective (Default) | ||

| DI6 | general input port, low-level propagation is effective (Default) | ||

| DI7 | general input port, low-level propagation is effective (Default) | ||

| DI8 | general input port, low-level propagation is effective (Default) | ||

| DI9 | general input port, low-level propagation is effective (Default) | ||

| DI10 | general input port, low-level propagation is effective (Default) | ||

| DI11 | general input port, low-level propagation is effective (Default) | ||

| DI12 | general input port, low-level propagation is effective (Default) | ||

| DI13 | general input port, low-level propagation is effective (Default) | ||

| DI14 | general input port, low-level propagation is effective (Default) | ||

| DI15 | general input port, low-level propagation is effective (Default) | ||

| 0V | Signal input public port | ||

| Ethernet | 1X | Industrial Ethernet interface | These four ports can be arbitrarily configured |

| 2X | Industrial Ethernet interface | ||

| 3X | Industrial Ethernet interface | ||

| 4X | Industrial Ethernet interface | ||

| General serial port | RS232 | RS232 serial port | It can butt-joint with laser |

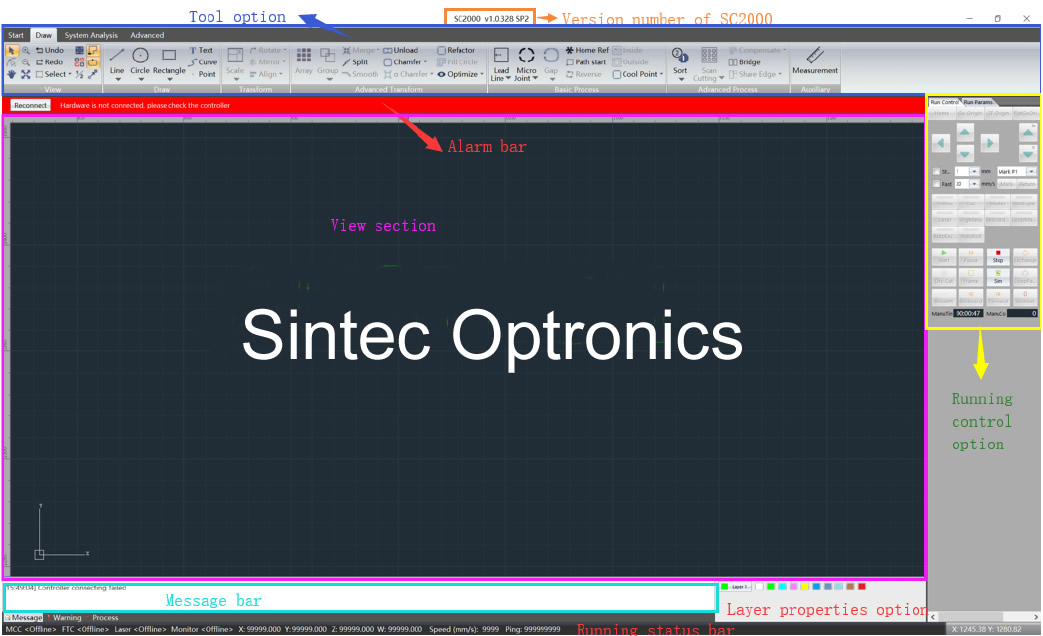

STAC-SC2000 CNC cutting software is designed for flat fiber laser cutting which includes graphic drawing and editing, cutting process dealing, cutting process controlling, system monitoring, components monitoring and debugging, and so on.

Features:

1) Simple Operations, Powerful Functions.

Developed based on RIBBON framework, the design is unique and the software is easy to be operated.

UI design is more humanized, which is easier to use even without training.

With powerful CAM functions based on AUTOCAD design, support graphic import, graphic drawing, graphic editing, and graphic transformation, graphic optimized and so on.

Intelligent capturing, which makes drawing more convenient and accurate.

Unique properties option design, which helps user to design the cutting graphic more easily.

Support various sort methods, auto sort can recognize the film inside or outside the graphic to make sure the path planning optimized.

Powerful lead line function, support various ways to lead line, auto added suitable lead line based on graphic nested relations. Support check/revise interfered lead line by one click.

2) Complete cutting process, debugging easily.

Support all kinds of cutting process: Section drill, gradual drill, multi stages drill, cutting with film, fix height cutting, and predrill and so on.

Support laser’s power/frequency adjusted with speed, to decrease or avoid the problem of firing corners when cutting carbon steel.

Support multilayer cutting or marking, and other sorts of processing ways.

Support micro-joint, gap, over-cutting, bridge, kerf-compensation and so on.

Powerful material database, which can save all sorts of material cutting process.

Support complex functions: Edge seeking, fly-cutting and so on.

Support breakdown position tracking/forward/backward and so on.

3) Rea-time alarm, stable and reliable.

Support running error measurement, it can check the error between running orbit and graphic error.

Real-time alarming the status of capacitive height controller, laser source, auxiliary gas of electric laser cutting head and other equipment, make sure the security during cutting.

More than 50 different kinds of alarms, to secure the equipment in whole aspect, avoid user’s wrong operation.

UI design is very clear, from up to down: title option, tool option, alarm option, view option, running control option, message bar, graphic parameters option, and status bar. The functions of each section shows as below:

| Section | Function | Remark |

| Tittle bar | Display software’s name and version number. | |

| Tool option | Mainly collects the tools needed for software operation, it has five submenu: Start/Draw/System Analysis/Advanced/Nest. User can do graphic drawing, graphic editing, graphic transformation, adding lead line, monitoring running status, configuration machine tool. | |

| Alarm bar | Display the current system alarm. | Alarm will be displayed in pop-up window, and once the alarm is cleared, the pop-up window will be gone. |

| View section | Graphic drawing/displaying section, displaying section of the machine’s cutting area. | |

| Running control option | Run all kinds of cutting actions by software. | |

| Message bar | Display the current running status in scrolling to attract user’s attention. | |

| Layer properties option | Set up layer properties such as layer process, graphic transformation and so on. | |

| Running status | Display the running status, running location, cutting speed and so on. |

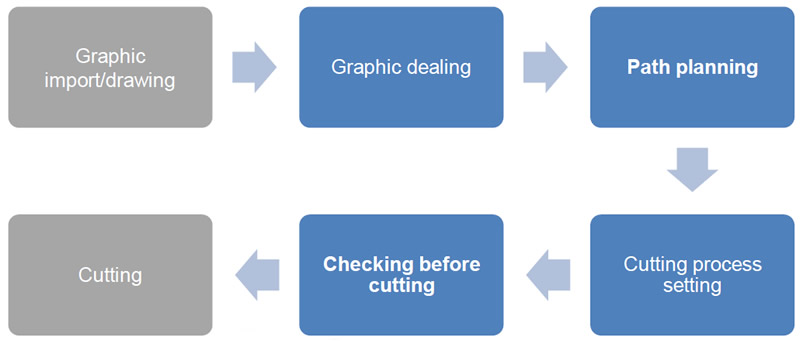

Operation flowchart:

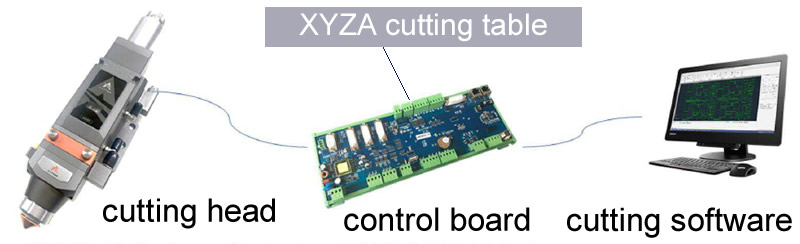

A full package consists of a laser cutting head, a control board and cutting software.

The functions of each part is summarized as following:

| Part name | Part number/combination | Remarks |

| Cutting head | STAC-A200MS | <2kW, manual focusing |

| Cutting head | STAC-A200MS-3D | <2kW, manual focusing, smaller 3D nozzle size for tube cutting |

| Cutting head | STAC-A260E | <2kW, electrical focusing |

| Cutting head | STAC-A290E | <2kW, electrical focusing, smaller 3D nozzle size for tube cutting |

| Cutting head | STAC-A280E | <4kW, electrical focusing |

| Cutting head | STAC-A295E | <4kW, electrical focusing, smaller 3D nozzle size for tube cutting |

| Control system | STAC-MCC3721H + STAC-SC2000 | 3-axis (X, Y1, Y2, Z) flat-plate cutting. Y1 & Y2 have same signals. |

| Control system | STAC-MCC3721NC + STAC-SC2000 | 4-axis (X, Y1, Y2, Z, A) flat-plate cutting. A is used to exchange tables. |

| Control system | STAC-MCC3723+STAC-FTC10+SCTube | Tubing cutting such as round, square, L, H and rotation |

| Control system | STAC-MCC3723+STAC-FTC10+STAC-EX15*2+SCTube | Tubing & flat plate cutting |

| Total solution | STAC-A200MS+STAC-3721H+STAC-SC2000 | Internal height floating, for thin flat plate cutting |

| Total solution | STAC-A260E+STAC-MCC3721NC+STAC-SC2000 | Internal height floating and auto-focusing, for thick flat plate cutting |

| Total solution | STAC-A200MS-3D+STAC-MCC3723+STAC-FTC10+STAC-SCTube | Professional tubing cutting such as round, square, L, H and rotation |

| Height floating | STAC-FTC10 (not including sensor nozzle) | Individual height adjusting, for tubing, flat-plate, 3D cutting |

| Height floating | STAC-FTC61 (not including sensor nozzle) | Individual height adjusting, supporting pulse step or servo motors |

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616