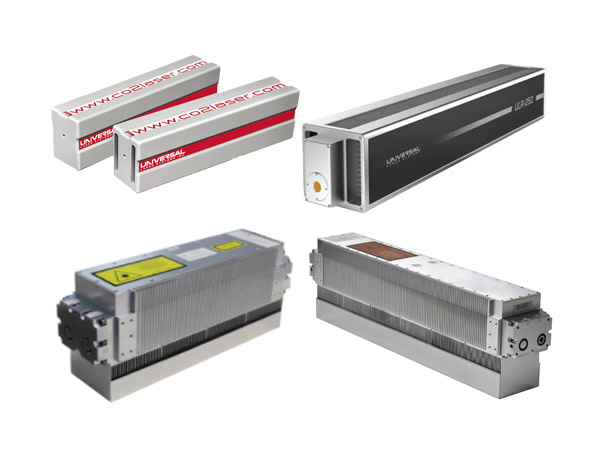

These RF-excited CO2 lasers are professionally made and are widely used in the processing of non-metals such as plastic organic materials BBS etc. CO2 laser tube is based on our proven ceramic core technology.

We are a reliable company for expert advice and good service in the field of CO2 laser beam source. Superior beam quality, favourable price, long product lifetime, efficient technical support are the main strengths of our products and service.

CO2 fractional laser scare removal skin resurfacing device

CO2 laser therapy

RF stretch marks removal CO2 fractional laser machine

RF tube laser generator vaginal tightening laser

Cosmetology surgery apparatus

Achieve high speed static or dynamic online marking code

Mark/engrave clearly

Hard-wearing quality

High engraving and marking efficiency

Environmentally-friendly

High and stable power

Cutting better than fiber laser for non-metal

The speed of cutting is faster

Cutting leather, wood, plastics etc

3-5 years long lifetime, stable machine and mode quality

All metal body and very firm

Small size and easy to carry

Quick response time for services

| Model | STD-xxx-30A/W | STD-xxx-55A/W |

| Wavelength | 9.3 / 10.2 / 10.6μm | 9.3 / 10.6μm |

| CW Output Power | ≥30W | ≥55W |

| Power Stability | <±5% | <±5% |

| Mode | >98%TEM00 | >98%TEM00 |

| Beam Size | 1.8±0.2㎜ | 1.8±0.2㎜ |

| Beam Divergence | 7.5±0.5 mrad | 7.5±0.5 mrad |

| Mode Quality | M²<1.2 | M²<1.2 |

| Polarization | >100:1 linear | >100:1 linear |

| Weight of Laser System | 5.2kg | 10kg |

| Dimension | 357×92.5×142mm | 492.5x92.5x154.5mm |

| Input voltage | 48 VDC <±2% | 48 VDC <±2% |

| Input DC current | ≤12A | ≤20A |

| Ambient Air Temperature | 5℃ to 40℃ | 5℃ to 40℃ |

| Cooling | Air or water | Air or water |

| Humidity | Non-condensing | Non-condensing |

Laser power is tested at the room temperature 25degree. When the temperature rises 1℃, the output power will reduce 1%.

Definition of stabilization: ±(Pmax-Pmin)/(2Pmax)

Testing condition of stabilization: warming up about 10mins, controlling duty cycle constantly, under the normal operating environment.

STD-xxx-yyz, where xxx means laser wavelength in um (9.3 or 10.6), yy means laser power in watt, and z means cooling in A for air cooling or W for water cooling.

| PIN NO | SIGNAL DESCRIPTION |

| 1 (PWM Orange and white) | RF Enable TTL logic input 1=RF ON,0=RF OFF;1KΩ impedance. This input turns on the laser. (See also Pin 7, Control Enable, below) |

| 2 (+15V Orange) | +15 VDC±0.5VDC,0.25 A Max output for customer use |

| 3 (Laser Green and white) | Laser ok TTL logic output,1=LASER OK,0=LASER Fault; Output is asserted when no faults (SWR, Temp or Volt.)are detected |

| 4 (Temp Blue) | Temperature OK TTL logical output,1=Temp ok,0=Temp fault; Output is asserted when temperature is below 60℃ |

| 5 (Volt Blue and white) | Power and voltage OK TTL logical output;1= voltage ok,0=voltage fault; Output is asserted when DC supply voltage is below max. value |

| 6 (GND Green) | For internal use. must be grounded |

| 7 (Enable Brown and white) | Control enables TTL Logical input;1= Laser control enable,0= Laser controlled disabled This input must be asserted before RF enable can be used to turn on the laser. |

| 8 (GND Brown) | GND |

| Model | STJ-xxx-20W | STJ-xxx-30L | STJ-xxx-30W | STJ-xxx-60W |

| Wavelength | 10.6/10.2/9.3μm | 10.6/10.2/9.3μm | 10.6/10.2/9.3μm | 10.6/10.2/9.3μm |

| Laser power | ≥28W | ≥33W | ≥40W | ≥65W |

| Power stability | ±5% | ±5% | ±5% | ±5% |

| Beam mode | TEM00 | TEM00 | TEM00 | TEM00 |

| Beam diameter | 2.0-2.2mm | 2.0-2.2mm | 2.0-2.2mm | 2.5-3.0mm |

| Beam divergence | 4mrad | 4mrad | 4mrad | 4mrad |

| Polorization | 50:1, vertical | 50:1, vertical | 50:1, vertical | 50:1, vertical |

| Modulation frequency | 0-20 kHz | 0-20 kHz | 0-20 kHz | 0-20 kHz |

| Cooling | Air | Air | Air | Air |

| DC power input | 48VDC/12.5A/600W | 48VDC/12.5A/600W | 48VDC/12.5A/600W | 48VDC/31A/1500W |

| Dimension, mm | 360×93×140 | 360×93×140 | 360×93×140 | 537×93×140 |

The ULR series of CO2 lasers for OEM use are based on a sealed, RF pumped, slab design that produces a high-quality beam. These lasers can be operated in CW mode or modulated to control average power. Modulation is accomplished by varying the pulse width of the input signal.

In the 10 W to 150 W lasers, RF electrodes are spaced apart to allow the laser beam to form without influence of the electrodes, delivery excellent near- and far-field quality with minimal wave-guide effects. The folded resonator design allows generation of power in a compact package. Our lasers require no consumables and deliver a very long lifetime.

When you purchase an OEM laser you are not only buying a laser source, but a partnership. That partnership means you receive direct access to world-wide technical support and the shortest service turnaround times, access to the most advanced Applications Laboratory and the most robust and reliable lasers on the market for as long as you own and use the product.

Space Saving and Easily Integrated: The patented multi-pass, slab resonator design is the foundation of our robust and highly reliable laser sources. Our integrated air-cooled and internally RF-stimulated lasers eliminate the need for additional space and cost for chillers, and external power sources. Integrating the aser sources into your production or research process is as easy plugging it in.

Broad Product Line of Air-cooled Options: We manufacture single resonator air-cooled lasers in power ranging from 10-75 and 250 watts and dual resonator lasers at the 100, 120, 150watt range.

Unbeatable New Order Delivery Lead Time: 10 Business days for a new OEM single resonator ULR 10W to 75 W lasers.13 Business days for a new OEM ULR dual resonator, and laser sources over 100 W.

Reliability: Average field life between reconditioning in excess of 6.5 years.

Shortest Service Turn Around Time on the Market: As the laser manufacturer, we deliver the shortest service time on the market. We recondition and return your laser in 16 Business days.

State-of-the-Art Materials Application Laboratory: Our material scientists and applications engineers work with our customers to understand their unique materials processing requirements. Years of industry experience is put to work in developing a customized laser processing solution. Processed materials samples and a report describing laser configuration and processing recommendations are provided.

90-Day Risk Free Laser Evaluation Program: To assure your complete satisfaction, we offer a risk free laser evaluation program. Examine our innovative, space-saving, air-cooled CO2 Lasers in your application with no risk for 90-days.

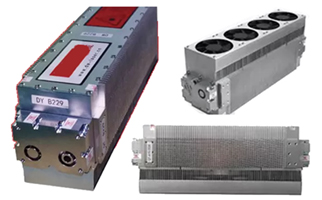

Two cooling options are available:

Integrated Air: ULR lasers configured for integrated air cooling contain fans and heat sinks designed to allow the laser to operate efficiently with no external cooling.

Basic Air: ULR lasers configured for basic air cooling do not include fans. The integrator is responsible for ensuring adequate cooling, per ULS specifications.

10.6µ and 9.3µ configurations available

TTL-compatible Over-temperature warning and laser status features

Thermal cutoff protection

Low-profile mounting plate

RoHS compliant

RS485 communication

48V DC Input Voltage

| Laser power | Basic air | Integrated air | 9.3um |

| 10W | Y | Y | Y |

| 25W | Y | Y | Y |

| 30W | Y | Y | Y |

| 40W | Y | Y | Y |

| 50W | Y | Y | Y |

| 60W | Y | Y | |

| 75W | Y | Y | |

| 100W | Y | Y | |

| 120W | Y | Y | |

| 150W | Y | Y |

| Model | ULR10 | ULR25/ULR30 | ULR40 | ULR50/ULR60 | ULR75 |

| Rated power** | 10W | 25W or 30W | 40W | 50W or 60W | 75W |

| Wavelength | 10.6um | 10.6um/9.3um | 10.6um/9.3um | 10.6um/9.3um | 10.6um |

| Power stability | ±10% | ±5% | ±5% | ±5% | ±10% |

| M2 | <1.3±0.2 | <1.3±0.2 | <1.3±0.2 | <1.3±0.2 | <1.3±0.2 |

| Beam size(near field) | 4±1mm | 4±1mm | 4±1mm | 4±1mm | 4±1mm |

| Beam pergence(full angle) | 5±1mrad | 5±1mrad | 5±1mrad | 5±1mrad | 5±1mrad |

| Polarization | Linear | Linear | Linear | Linear | Linear |

| Pointing stability | 200μrad | 200μrad | 200μrad | 200μrad | 200μrad |

| Rise time | 120±40μS | 120±40μS | 120±40μS | 120±40μS | 120±40μS |

| Duty cycle | 0-100% | 0-100% | 0-100% | 0-100% | 0-100% |

| Modulation signal type | TT | TTL | TTL | TTL | TTL |

| Cooling | Air | Air | Air | Air | Air |

| Weight (Basic AC) | 3.3kg | 8.1kg | 9.5kg | 10.9kg | |

| Weight (Basic WC) | 3.3kg | 9.0kg | 10.4kg | 11.8kg | |

| Weight (Integrated AC) | 3.9kg | 9.0kg | 10.4kg | 11.8kg | 14kg |

| Weight (integrated WC) | 3.9kg | 9.0kg | 10.4kg | 11.8kg | 14kg |

| Ambient temperature*** | 10-35oC | 10-35oC | 10-35oC | 10-35oC | 10-35oC |

| Relative humidity | <90% | <90% | <90% | <90% | <90% |

| DC input voltage | 48VDC | 48VDC | 48VDC | 48VDC | 48VDC |

| RMS current (CW) | 4A | 10A | 14A | 18A | 20A |

| Model | ULR100 | ULR120 | ULR150 |

| Rated power** | 100W | 120W | 150W |

| Wavelength | 10.6um | 10.6um | 10.6um |

| Power stability | ±5% | ±5% | ±5% |

| M2 | <1.3±0.2 | <1.3±0.2 | <1.3±0.2 |

| Beam size(near field) | 8±1mm | 4±1mm | 4±1mm |

| Beam pergence(full angle) | 5±1mrad | 5±1mrad | 5±1mrad |

| Polarization | Cross polarized | Cross polarized | Cross polarized |

| Pointing stability | 200μrad | 200μrad | 200μrad |

| Rise time | 120±40μS | 120±40μS | 120±40μS |

| Duty cycle | 0-100% | 0-100% | 0-100% |

| Modulation signal type | TTL | TTL | TTL |

| Cooling | Air | Air | Air |

| Weight (Integrated AC) | 36.7kg | 36.7kg | 43.0kg |

| Weight (integrated WC) | 36.7kg | 36.7kg | 43.0kg |

| Ambient temperature*** | 10-35oC | 10-35oC | 10-35oC |

| Relative humidity | <90% | <90% | <90% |

| DC input voltage | 48VDC | 48VDC | 48VDC |

| RMS current (CW) | 36A | 36A | 40A |

The bottom and connector are swallow-tailed and 12PIN respectively but the bottom and connector are flat and 15PIN respectively. There is no difference on performance.

For used Universal lasers, we provide fully-refurbishing services at very low prices. The refurbishing includes replacing optics, RF power supply and refilling gas. All the jobs will be finished within 7 days.

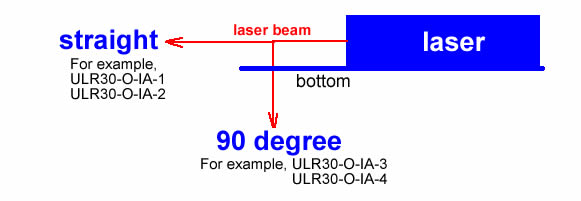

With the 90 degree output the beam goes through the base plate. We cut a hole in the bottom and mount it to the face of the laser, turn it 90 degree down through the hole. We can not offer it in any other direction but through the bottom of the base plate. To offer this option on OEM lasers the beam output number is (#3) for 90 degree without pointer, (#4) for the 90 degree with pointer. This option is not offered on 10W Integrated air cooled due to the small base plate and no room to mount the out put.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616