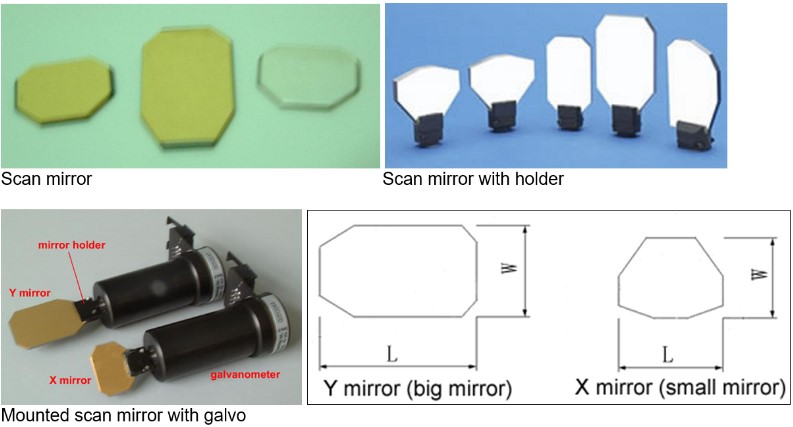

The scan mirrors are rectangular mirror of light weight. They are to be used for high speed two-axis laser scanning system. Y mirror is larger than X mirror since the beam on the Y mirror is reflected from the X mirror.

The scan mirrors are rectangular mirror of light weight. They are to be used for high speed two-axis laser scanning system. The dimensions of each mirror have been calculated to allow for scanning of a laser beam with no beam spill over at the extrems of scan. Y mirror is larger than X mirror since the beam on the Y mirror is reflected from the X mirror. The mirrors have high reflectivities of 99.7% or above and so may be safe at high powers.

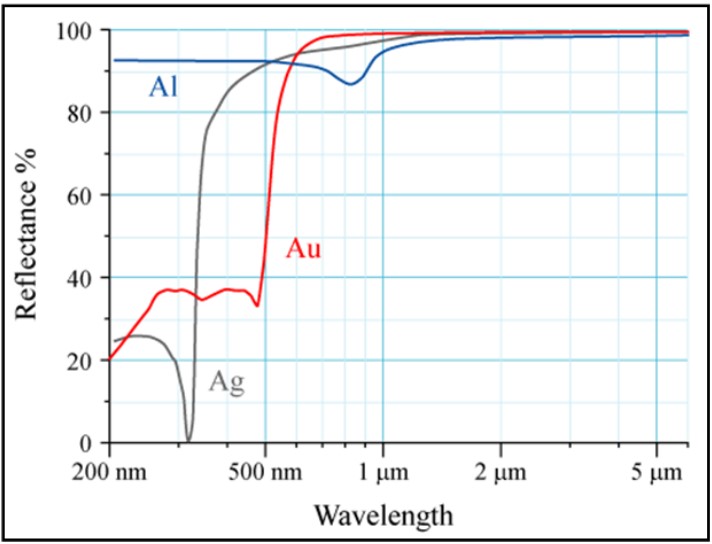

The high-reflectivity film ia coated on the mirror surface. Gold coating is used on silicom at 10.6um, dielectric coating is used on fused silicon at UV range (344nm to 244nm), dielectric coating is also used on BK7/fused silicon at green or visible range (650nm/532nm), dielectric coating or silver coating is used on Si/BK7/FS for Nd:YAG or fiber lasers.

Model Description: SMWxxxx-xxA-LxWxT-Dx

Example: SMW1064-12X-21x16.8x2-D5, mounted X mirror at 1064nm wavelength, mirror dimension 21x16x22mm, hole diameter of mirror holder 5mm, dielectric coating at 1064nm

| Part number | Wavelength um/nm | Max. input beam dia. mm | Dimension mm | Substrate |

| SMW10.6/650-7X-13x12x1 | 10.6/650 | 7 | 13x12x1 | Si |

| SMW10.6/650-7Y-16x10x1 | 10.6/650 | 7 | 16x10x1 | Si |

| SMW10.6/650-8X-15x12.2x1 | 10.6/650 | 8 | 15x12.2x1 | Si |

| SMW10.6/650-8Y-20.5x12.8x1 | 10.6/650 | 8 | 20.5x12.8x1 | Si |

| SMW10.6/650-8X-15.7x11x1.5 | 10.6/650 | 8 | 15.7x11x1.5 | Si |

| SMW10.6/650-8Y-21x12.2x1.5 | 10.6/650 | 8 | 21x12.2x1.5 | Si |

| SMW10.6/650-8.5X-14.8x11.4x1.6 | 10.6/650 | 8.5 | 14.8x11.4x1.6 | Si |

| SMW10.6/650-8.5Y-20.2x12.3x1.6 | 10.6/650 | 8.5 | 20.2x12.3x1.6 | Si |

| SMW10.6/650-10X-19x15.5x1.5 | 10.6/650 | 10 | 19x15.5x1.5 | Si |

| SMW10.6/650-10Y-26.5x17x1.5 | 10.6/650 | 10 | 26.5x17x1.5 | Si |

| SMW10.6/650-10X-16x13.2x1.5 | 10.6/650 | 10 | 16x13.2x1.5 | Si |

| SMW10.6/650-10Y-22x14x1.5 | 10.6/650 | 10 | 22x14x1.5 | Si |

| SMW10.6/650-10X-18.4x13x2 | 10.6/650 | 10 | 18.4x13x2 | Si |

| SMW10.6/650-10Y-23.3x15.9x2 | 10.6/650 | 10 | 23.3x15.9x2 | Si |

| SMW10.6/650-10X-18.7x14.6x1.22 | 10.6/650 | 10 | 18.7x14.6x1.22 | Si |

| SMW10.6/650-10Y-23.1x15.9x1.78 | 10.6/650 | 10 | 23.1x15.9x1.78 | Si |

| SMW10.6/650-10X-12.7x12.5x1 | 10.6/650 | 10 | 12.7x12.5x1 | Si |

| SMW10.6/650-10Y-18x12.7x1 | 10.6/650 | 10 | 18x12.7x1 | Si |

| SMW10.6/650-12X-21x16.8x2 | 10.6/650 | 12 | 21x16.8x2 | Si |

| SMW10.6/650-12Y-30x19x2 | 10.6/650 | 12 | 30x19x2 | Si |

| SMW10.6/650-12X-21x16.8x2 | 10.6/650 | 12 | 21x16.8x2 | Si |

| SMW10.6/650-12Y-26x17x2 | 10.6/650 | 12 | 26x17x2 | Si |

| SMW10.6/650-12X-24x16.5x3 | 10.6/650 | 12 | 24x16.5x3 | Si |

| SMW10.6/650-12Y-30x21.5x3 | 10.6/650 | 12 | 30x21.5x3 | Si |

| SMW10.6/650-12X-21.8x17x2 | 10.6/650 | 12 | 21.8x17x2 | Si |

| SMW10.6/650-12Y-30x19x2 | 10.6/650 | 12 | 30x19x2 | Si |

| SMW10.6/650-12X-24x16x2.9 | 10.6/650 | 12 | 24x16x2.9 | Si |

| SMW10.6/650-12Y-30.8x21.5x2.9 | 10.6/650 | 12 | 30.8x21.5x2.9 | Si |

| SMW10.6/650-14X-25x19x2 | 10.6/650 | 14 | 25x19x2 | Si |

| SMW10.6/650-14Y-32x21x2 | 10.6/650 | 14 | 32x21x2 | Si |

| SMW10.6/650-15X-27x20x2.5 | 10.6/650 | 15 | 27x20x2.5 | Si |

| SMW10.6/650-15Y-37.6x22.6x2.5 | 10.6/650 | 15 | 37.6x22.6x2.5 | Si |

| SMW10.6/650-16X-27x20x2.5 | 10.6/650 | 16 | 27x20x2.5 | Si |

| SMW10.6/650-16Y-37.5x22.5.2.5 | 10.6/650 | 16 | 37.5x22.5.2.5 | Si |

| SMW10.6/650-18X-27x23x2.5 | 10.6/650 | 18 | 27x23x2.5 | Si |

| SMW10.6/650-18Y-40x26.2x2.5 | 10.6/650 | 18 | 40x26.2x2.5 | Si |

| SMW10.6/650-20X-35x25x2 | 10.6/650 | 20 | 35x25x2 | Si |

| SMW10.6/650-20Y-35x30x2 | 10.6/650 | 20 | 35x30x2 | Si |

| SMW10.6/650-20X-37x25.5x3 | 10.6/650 | 20 | 37x25.5x3 | Si |

| SMW10.6/650-20Y-47x31x3 | 10.6/650 | 20 | 47x31x3 | Si |

| SMW10.6/650-20X-35.6x25x4 | 10.6/650 | 20 | 35.6x25x4 | Si |

| SMW10.6/650-20Y-46x31x4 | 10.6/650 | 20 | 46x31x4 | Si |

| SMW10.6/650-20X-37x25x3 | 10.6/650 | 20 | 37x25x3 | Si |

| SMW10.6/650-20Y-47.5x31x3 | 10.6/650 | 20 | 47.5x31x3 | Si |

| SMW10.6/650-20X-35.7x25.5x5.5 | 10.6/650 | 20 | 35.7x25.5x5.5 | Si |

| SMW10.6/650-20Y-48.5x32x4.1 | 10.6/650 | 20 | 48.5x32x4.1 | Si |

| SMW10.6/650-20X-37x25x3 | 10.6/650 | 20 | 37x25x3 | Si |

| SMW10.6/650-20Y-47x31x3 | 10.6/650 | 20 | 47x31x3 | Si |

| SMW10.6/650-25X-45.2x30.1x2.4 | 10.6/650 | 25 | 45.2x30.1x2.4 | Si |

| SMW10.6/650-25Y-56.5x38.94x2.4 | 10.6/650 | 25 | 56.5x38.94x2.4 | Si |

| SMW10.6/650-30X-57x37.8x4 | 10.6/650 | 30 | 57x37.8x4 | Si |

| SMW10.6/650-30Y-67x45x4 | 10.6/650 | 30 | 67x45x4 | Si |

| SMW10.6/650-30X-54x35x3.5 | 10.6/650 | 30 | 54x35x3.5 | Si |

| SMW10.6/650-30Y-62x43x3.5 | 10.6/650 | 30 | 62x43x3.5 | Si |

| SMW10.6/650-30X-55x33x4 | 10.6/650 | 30 | 55x33x4 | Si |

| SMW10.6/650-30Y-68.5x46x4 | 10.6/650 | 30 | 68.5x46x4 | Si |

| SMW10.6/650-30X-55x34x4 | 10.6/650 | 30 | 55x34x4 | Si |

| SMW10.6/650-30Y-63x43x4 | 10.6/650 | 30 | 63x43x4 | Si |

| SMW10.6/650-30X-55x34x3 | 10.6/650 | 30 | 55x34x3 | Si |

| SMW10.6/650-30Y-63x43x3 | 10.6/650 | 30 | 63x43x3 | Si |

| SMW10.6/650-40X-72x49x5 | 10.6/650 | 40 | 72x49x5 | Si |

| SMW10.6/650-40Y-91x61x4.5 | 10.6/650 | 40 | 91x61x4.5 | Si |

| Part number | Wavelength nm | Max. input beam dia. mm | Dimension mm | Substrate |

| SMW1064/650-8X-12x10x1 | 1064/650 | 8 | 12x10x1 | Si |

| SMW1064/650-8Y-16x11x1 | 1064/650 | 8 | 16x11x1 | Si |

| SMW1064/650-10X18.4x13x2 | 1064/650 | 10 | 18.4x13x2 | Si |

| SMW1064/650-10Y-23.3x15.9x2 | 1064/650 | 10 | 23.3x15.9x2 | Si |

| SMW1064/650-10X-18x13x1.5 | 1064/650 | 10 | 18x13x1.5 | Si |

| SMW1064/650-10Y-24.3x15.7x1.5 | 1064/650 | 10 | 24.3x15.7x1.5 | Si |

| SMW1064/650-10X-18.3x13x1.9 | 1064/650 | 10 | 18.3x13x1.9 | K9 |

| SMW1064/650-10Y-23.2x16x1.9 | 1064/650 | 10 | 23.2x16x1.9 | K9 |

| SMW1064/650-10X-18.4x13x1.5 | 1064/650 | 10 | 18.4x13x1.5 | Si |

| SMW1064/650-10Y-23.3x15.9x1.5 | 1064/650 | 10 | 23.3x15.9x1.5 | Si |

| SMW1064/650-16X-28x20x2 | 1064/650 | 16 | 28x20x2 | K9 |

| SMW1064/650-16Y-39x23x2 | 1064/650 | 16 | 39x23x2 | K9 |

| SMW1064/650-18X-27x23x2.5 | 1064/650 | 18 | 27x23x2.5 | Si |

| SMW1064/650-18Y-40x26x2.5 | 1064/650 | 18 | 40x26x2.5 | Si |

| SMW1064/650-20X-37x24x2.5 | 1064/650 | 20 | 37x24x2.5 | K9 |

| SMW1064/650-20Y-49x31x2.5 | 1064/650 | 20 | 49x31x2.5 | K9 |

| SMW1064/650-20X-35.7x25.5x5.5 | 1064/650 | 20 | 35.7x25.5x5.5 | Si |

| SMW1064/650-20Y-48.5x32x4.1 | 1064/650 | 20 | 48.5x32x4.1 | Si |

| Part number | Wavelength nm | Max. input beam dia. mm | Dimension mm | Substrate |

| SMW532-10X-18.3x13x2 | 532 | 10 | 18.3x13x2 | Si |

| SMW532-10Y-23.2x16x2 | 532 | 10 | 23.2x16x2 | Si |

| SMW532/650-15X-27x20x2.5 | 532/650 | 15 | 27x20x2.5 | Si |

| SMW532/650-15Y-37.6x22.6x2.5 | 532/650 | 15 | 37.6x22.6x2.5 | Si |

| Part number | Wavelength nm | Max. input beam dia. mm | Dimension mm | Substrate |

| SMW248/650-30X-54x35x4 | 248/650 | 30 | 54x35x4 | Si |

| SMW248/650-30Y-62x43x4 | 248/650 | 30 | 62x43x4 | Si |

| SMW355/650-10X-18x13x1.5 | 355/650 | 10 | 18x13x1.5 | Si |

| SMW355/650-10Y-24.3x15.7x1.5 | 355/650 | 10 | 24.3x15.7x1.5 | Si |

| SMW355/650-10X-27x20x2.5 | 355/650 | 15 | 27x20x2.5 | Si |

| SMW355/650-10Y-37.6x22.6x2.5 | 355/650 | 15 | 37.6x22.6x2.5 | Si |

Custom-made scan mirrors are available and please contact us for more information.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 10 Bukit Batok Crescent #07-02 The Spire Singapore 658079

Tel: +65 63167112

Fax: +65 63167113

Whatsapp: +65 91904616